Types of Zinc Alloys for Die Casting worldwide

In China, zinc die-casting alloys are manufactured in accordance with national standard GB/T 8731, which aligns closely with international specifications such as ASTM B86, EN 1774 and JIS H 5302. These alloys offer a range of mechanical properties suited to diverse applications, from decorative housings to high-strength engineering components.

Common Alloys and Their Characteristics

Zamak 3 (ZL043 / ZnAl4)

The most widely used zinc alloy for die casting, valued for its excellent fluidity, dimensional stability and surface finish.

- Typical Composition

– Aluminium (Al): 4.0 %

– Magnesium (Mg): 0.03 %

– Copper (Cu): ≤ 0.02 %

– Iron (Fe): ≤ 0.005 %

– Zinc (Zn): Balance - Key Properties

– Density: 6.6 g/cm³

– Tensile strength: 280 MPa

– Elongation: 10 %

– Good corrosion resistance and impact strength

Zamak 5 (ZL045 / ZnAl4Cu1)

An enhancement of Zamak 3, with 1 % copper to increase hardness and abrasion resistance, albeit with a slight reduction in ductility.

- Typical Composition

– Aluminium: 4.0 %

– Copper: 1.0 %

– Magnesium: 0.03 %

– Iron: ≤ 0.005 %

– Zinc: Balance - Key Properties

– Density: 6.7 g/cm³

– Tensile strength: 320 MPa

– Hardness and wear resistance superior to Zamak 3

– Elongation: ~7 %

Zamak 2 (ZL042 / ZnAl4Cu3)

Known as a high-strength alloy, used primarily for components subject to significant wear or mechanical load.

- Typical Composition

– Aluminium: 4.0 %

– Copper: 2.5–3.0 %

– Magnesium: 0.05 %

– Zinc: Balance - Key Properties

– High hardness and tensile strength (~350 MPa)

– Elongation: ~3 %

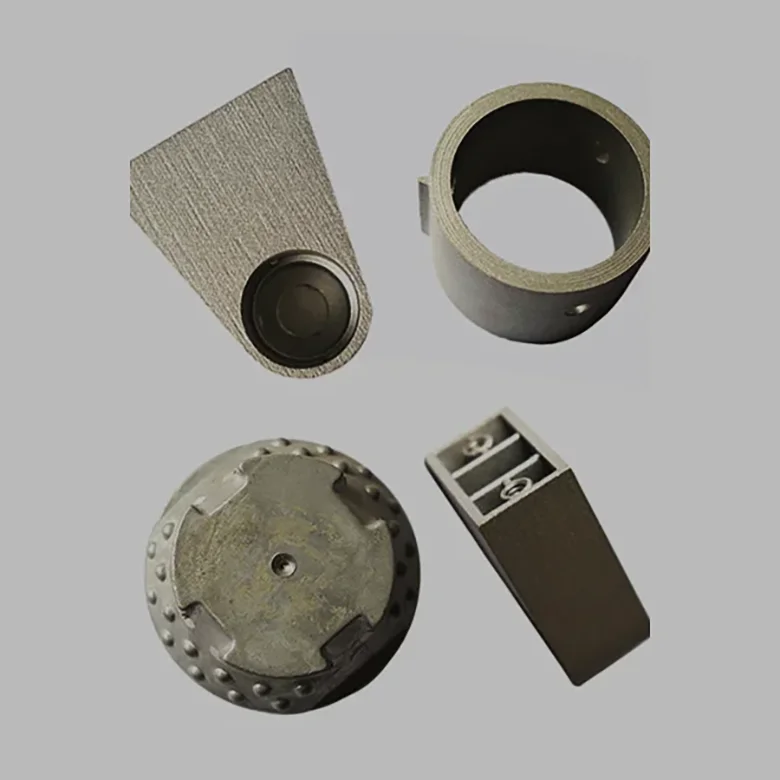

– Suitable for heavy-duty parts such as bearings and bushings

ZA-8 (ZL081 / ZnAl8Cu1)

Contains 8 % aluminium for enhanced creep resistance and strength; compatible with both hot- and cold-chamber die casting.

- Typical Composition

– Aluminium: 8.0 %

– Copper: 1.0 %

– Magnesium: 0.02 %

– Zinc: Balance - Key Properties

– Tensile strength: ~380 MPa

– Elongation: ~5 %

– Excellent dimensional stability, though with reduced fluidity compared to Zamak 3

ZA-12 and ZA-27

These alloys contain higher aluminium content (12 % and 27 % respectively) and are employed where very high mechanical strength is essential. They typically require cold-chamber processes and are less common in general-purpose die casting.

| Alloy | Al (%) | Cu (%) | Mg (%) | Tensile Strength (MPa) | Elongation (%) | Typical Applications |

|---|---|---|---|---|---|---|

| Zamak 3 | 4.0 | ≤ 0.02 | 0.03 | 280 | 10 | General die casting, enclosures, toys |

| Zamak 5 | 4.0 | 1.0 | 0.03 | 320 | 7 | Gears, handles, wear-resistant parts |

| Zamak 2 | 4.0 | 2.5 – 3.0 | 0.05 | 350 | 3 | Heavy-duty mechanical components |

| ZA-8 | 8.0 | 1.0 | 0.02 | 380 | 5 | Structural housings, high-strength parts |

Equivalent National and International Standards

Hot-chamber die-casting alloys closely matching the compositions specified in GB/T 8731 are also employed beyond China. In particular, grades equivalent to ZL043 and ZL045 remain the most widely adopted worldwide.

| EN 12844 Short Designation | China (GB∕T 8731) | USA (ASTM B240∕B669) | USA (SAE) | Japan (JIS H 5301) | ISO (H 5301) | UNS |

|---|---|---|---|---|---|---|

| ZP3 | ZL043 (ZnAl4) | AG40A | 903 | ZDC-2 | – | Z33520 |

| ZP5 | ZL045 (ZnAl4Cu1) | AG41A | 925 | ZDC-1 | – | Z35531 |

| ZP2 | ZL042 (ZnAl4Cu3) | AC43A | 921 | – | – | Z35541 |

| ZP8 | ZL081 (ZnAl8Cu1) | ZA8 | – | – | – | Z35636 |

China (GB/T 8731) entries use the ZL-series designations commonly specified in Chinese foundry standards.

The EN 12844 Short Designation (ZP3–ZP8) corresponds directly to those ZL alloys.

Other columns show the nearest equivalent grades in ASTM, SAE, JIS and UNS systems.

Chemical Composition Standards and Impurity Control

The above compositions refer to castings; the ingot and liquid alloy specifications (as defined in EN 1774: “Alloys for foundry purposes – Ingot and liquid”) are slightly broader to accommodate production tolerances. Close control of alloying elements and impurities is essential:

- Aluminium and Copper both increase strength and hardness; different ratios yield alloys tailored to fluidity, corrosion resistance and mechanical demands.

- Magnesium (up to ~0.1 %) improves corrosion resistance by mitigating interstitial corrosion, but excessive amounts (> 0.1 %) risk shrinkage cracks.

- Lead, cadmium and tin must be kept below ~0.005 % to avoid intergranular corrosion in humid environments.

- Iron and nickel are limited (< 0.05 %) to prevent the formation of hard intermetallics that impair machinability and impact strength.

- Silicon is restricted (< 0.03 – 0.045 %) for similar reasons.

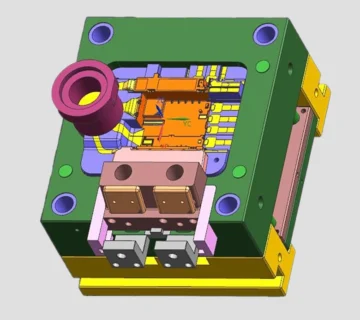

Die-Casting Process Parameters

| Alloy | Melt Temp. (°C) | Injection Speed | Shot Pressure (MPa) | Die Temp. (°C) |

|---|---|---|---|---|

| Zamak 3 | 390–430 | 0.5–1.0 m/s | 50–80 | 200–250 |

| Zamak 5 | 390–430 | 0.5–1.2 m/s | 55–85 | 200–250 |

| Zamak 2 | 400–430 | 0.5–1.0 m/s | 60–90 | 200–260 |

| ZA-8 | 420–450 | 0.4–0.8 m/s | 70–100 | 220–270 |

Hot-chamber: Typically used for Zamak alloys due to low melting range.

Cold-chamber: Required for higher-Al ZA-12/27 to avoid alloy corrosion of the injection mechanism.

Surface Finishing & Post-Processing

Chromate Conversion Coatings

Apply a thin, protective conversion layer to enhance corrosion resistance. For environmental and regulatory compliance (RoHS), specify a trivalent chromium (Cr³⁺) process rather than hexavalent chromium.

Powder coating and painting.

- Surface Preparation: Ensure the casting’s surface roughness is within 1–3 µm Ra.

- Cleaning and Pretreatment: Degrease and apply a phosphate or silane-based primer to encourage adhesion.

- Finishing: Use a polyester or epoxy powder; cure at 180–200 °C for 10–15 minutes.

Machinability

- Zamak 5: Allows higher spindle speeds (3,000 rpm or above) due to its increased hardness.

- Zamak 3: Best machined at 2,000–2,500 rpm for optimal surface finish.

- Recommended Feed Rates: 0.1–0.2 mm per revolution for final passes, irrespective of alloy, to minimise tool wear and achieve tight tolerances.

No comment