Definition and Characteristics

Shrinkage porosity – also referred to as shrink holes, shrinkage cavities, or looseness – is among the most frequent defects encountered in die castings. It arises when molten alloy contracts during solidification, and the liquid metal fails to compensate adequately, resulting in cavities within the casting.

These cavities are typically dark in colour, irregular in form, and coarse in texture.

By size and distribution, shrinkage-related defects are categorised as:

- Shrinkage cavities – large, concentrated voids.

- Micro-shrinkage (shrinkage porosity) – small, dispersed, honeycomb-like voids that reduce density.

In service, areas containing concentrated shrinkage porosity are particularly vulnerable to leakage, especially in water channels or heat-affected zones. Thermal cycling can cause the micro-voids to expand and interconnect, eventually forming leakage paths.

Defect Features

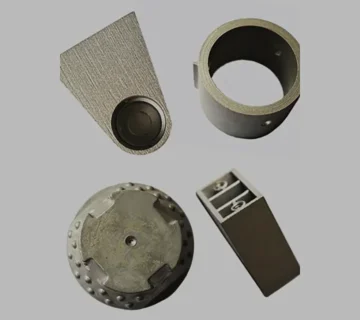

Shrinkage porosity is usually internal and must be detected through sectioning or non-destructive testing (NDT). It commonly appears in:

- Thick-walled regions

- Thermal nodes or hot spots

- Areas of high mould temperature

- Last-to-solidify zones of the alloy

Shrinkage porosity often coexists with gas porosity, resulting in combined defects. Fracture surfaces typically exhibit a coarse, porous morphology.

Types of Looseness (Porosity)

- Shrinkage Porosity

- Caused by volume contraction during solidification.

- Cavities form between dendritic arms where insufficient liquid metal is available to feed the space.

- Usually very small in scale and challenging to eliminate entirely.

- Gas Porosity

- Arises from excessive gas (primarily hydrogen) dissolved in the melt.

- During solidification, gas becomes trapped in interdendritic regions.

- Produces both microscopic and macroscopic voids.

- Core-Related Shrinkage

- Occurs at the ends of core rods or sand cores, which solidify last.

- Results in shrinkage cavities due to insufficient feeding.

- Corner Shrinkage

- Appears at corners or fillet radii where heat dissipation is poor.

- These zones solidify last and are prone to shrinkage if feeding is inadequate.

Causes of Shrinkage Porosity

- Excessive pouring temperature or prolonged overheating.

- Insufficient injection pressure or delayed application of intensification.

- Poor casting design with abrupt wall thickness changes or heavy sections.

- Large thermal nodes near ingates, cooling too slowly.

- Low filling ratio in the shot sleeve or thin biscuit, leading to reduced feeding.

- Localised high mould temperatures.

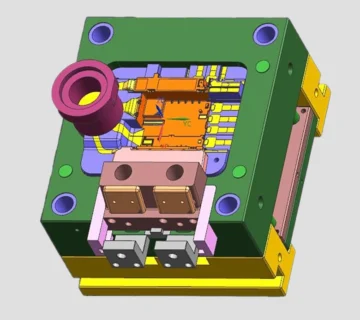

- Improper ingate design:

- Too thick → shrinkage near the ingate.

- Too thin → premature solidification restricting pressure transfer.

Countermeasures and Prevention

- Adhere to alloy melting specifications; avoid prolonged overheating.

- Reduce pouring temperature within safe limits.

- Increase intensification pressure and, if necessary, apply local squeeze pins.

- Optimise casting design:

- Eliminate heavy sections and hot spots.

- Smoothly transition between thin and thick walls.

- Consider inserts, hollow sections, or enhanced cooling.

- Use alloys with lower shrinkage rates or apply modification treatments.

- Improve gating and feeding design:

- Ensure efficient pressure transfer.

- Balance runner thickness and avoid turbulence.

- Select appropriate casting pressure and maintain holding pressure until ingates are fully solidified.

Key Notes

Every corrective action must be validated through process trials and must not compromise dimensional accuracy, surface quality, or mechanical performance.

No comment