Components of a Die Casting Mold

Die casting is a high-precision manufacturing process that involves injecting molten metal into a mold under high pressure to produce detailed and complex parts. The mould as a whole is central to ensuring the production of high-quality castings, and a clear understanding of mold components is essential for optimising the die casting process. Each mould element plays a specific role in achieving precision, durability, and efficiency in production. This article provides an in-depth exploration of a die-casting mould’s primary components, functions, and significance in the manufacturing process.

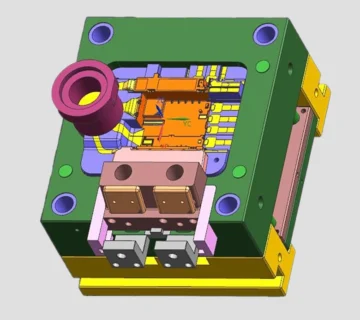

Cavity and Core: Defining the Shape

The cavity and core are the most critical parts of a die casting mold. Together, they create the outer and inner features of the final casting.

Cavity: The cavity is the hollow space within the mold that shapes the outer surface of the die casting. Its design is carefully crafted to match the specific geometry of the part to be produced. For instance, in automotive parts like engine blocks or transmission housings, the cavity may feature complex curves, internal ribs, and thin walls to match the required structural and aesthetic specifications. The cavity is typically made from high-strength tool steel, which can withstand the extreme temperatures and pressures of the die casting process.

Core: The core is used to create internal features or voids within the casting. For example, in an aluminum die casting for a housing unit, the core might be designed to form hollow chambers or specific internal passages that are necessary for functionality, such as airflow ducts in an electronic enclosure. Just like the cavity, the core is made from durable steel alloys, often with special coatings to reduce wear and increase longevity. It may also be water-cooled in high-precision applications to control thermal expansion.

Both cavity and core are precision-machined to exact tolerances to ensure the final product meets the specified design and functional requirements.

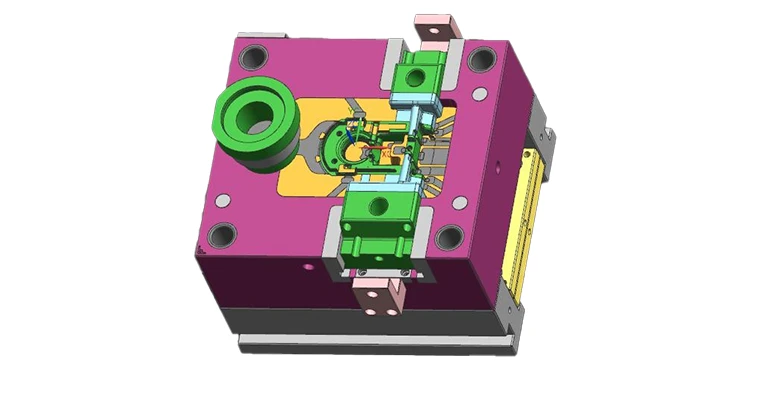

2. Die Blocks: The Structural Foundation

Die blocks provide the structural support for the entire mold, housing the cavity and core while withstanding the high pressures involved in the casting process.

- Fixed Die: This is the stationary half of the die mold, usually attached to the machine’s die-casting press. It contains the core and typically supports the main sections of the mold. In larger, more complex castings, the fixed die is often designed with multiple cavities to produce various parts simultaneously, increasing production efficiency. For example, in large-scale production of automotive parts, a fixed die might have a multi-cavity mold to make several castings in a single cycle.

- Moving Die: The moving dies (or ejector side) is half the mold opening and closing to allow the casting to be ejected. This die contains the cavity and typically uses ejector pins to push the part out once it has cooled and solidified. In producing precision die castings for the electronics industry, the moving die may be equipped with advanced hydraulic or pneumatic systems to ensure that it moves smoothly and efficiently without distortion, which is crucial for parts that require tight tolerances.

Die blocks are made from high-strength, wear-resistant steel alloys to ensure they can handle the repeated stresses and high temperatures encountered during the casting process.

Ejector Pins and Plate: Ensuring Smooth Ejection

Once the molten metal has cooled and solidified, the casting needs to be removed from the mold. This is accomplished using ejector pins and an ejector plate.

- Ejector Pins: Ejector pins are thin, cylindrical rods positioned within the moving die. When the casting is ready to be ejected, these pins push against the back of the part to break it free from the mold cavity. Ejector pins are critical in maintaining the quality of the casting by ensuring a smooth and clean ejection process. For example, in the casting of automotive engine components, ejector pins prevent part distortion by evenly distributing the pressure applied during the ejection process.

- Ejector Plate: The ejector plate is the mechanism that holds the ejector pins and moves them outward to eject the casting. In more advanced die casting systems, the ejector plate is often designed to work in tandem with automated robots, which further increase the efficiency and speed of the ejection process. For example, in high-volume production environments, such as those found in the aerospace or medical device industries, the ejector plate is part of a fully automated system that reduces human intervention and increases production speed.

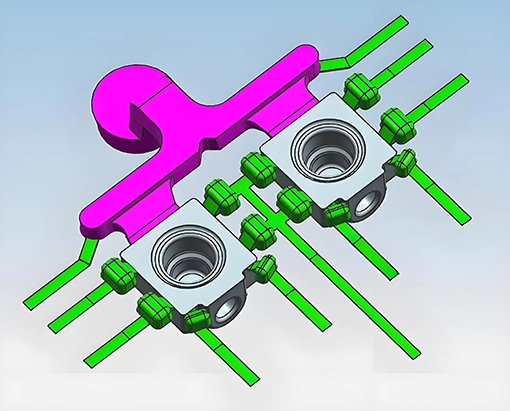

4. Sprue, Runner, and Gate: Directing the Flow of Molten Metal

The sprue, runner, and gate system plays an integral role in ensuring that molten metal is efficiently injected into the mold cavity without turbulence, ensuring smooth flow and reducing defects like cold shuts or voids.

- Sprue: The sprue is the entry point where molten metal flows into the mold. Positioned at the top of the mold, the sprue ensures that the metal is introduced under controlled conditions. In high-pressure die casting, the sprue often features a tapered design to accelerate the flow of metal into the runner system. For instance, in casting large components like pump housings, the sprue design is critical for minimizing air pockets and ensuring a consistent flow of metal.

- Runner: The runner is a channel that connects the sprue to the gates, which direct the molten metal into the mold cavity. A well-designed runner system minimizes the risk of metal solidifying before it reaches the cavity, ensuring a consistent fill. For complex castings, such as those used in the automotive industry, the runner system may include multiple channels to allow the molten metal to flow efficiently into various cavities simultaneously, reducing cycle time.

- Gate: The gate is the opening through which molten metal enters the cavity. The size, shape, and location of the gate are crucial factors that determine how well the metal fills the mold. For example, a strategically placed gate in a thin-walled part like a consumer electronics housing ensures that the molten metal fills the mold evenly and without turbulence. Gate design is often customized to match the flow characteristics of the metal and the part’s geometry.

5. Cooling Channels: Controlling the Solidification Rate

Cooling is one of the most crucial aspects of the die casting process, as it directly impacts the solidification time and the quality of the final part. Cooling channels are integrated into the mold to absorb heat from the molten metal and regulate the cooling rate.

- Cooling Channels: These are strategically placed channels that circulate coolant (usually water) around the mold. Cooling channels are essential for controlling the temperature of the mold and the solidification rate of the casting. In highly complex molds, such as those used in the aerospace industry, the cooling channels must be designed with precision to ensure uniform cooling across all surfaces of the casting. Poorly designed cooling systems can lead to uneven shrinkage, causing warping or dimensional inaccuracies in the final part.

- Cooling Efficiency: The efficiency of the cooling system is directly linked to the mold material and the channel design. Advances in mold design, such as conformal cooling channels that follow the shape of the part, have led to faster cooling rates and improved casting quality. In automotive die casting, for example, conformal cooling systems are becoming more common for creating parts with complex geometries and tight tolerances, as they significantly reduce cooling time and improve surface finish.

6. Vent System: Ensuring Airflow and Preventing Defects

Proper venting is essential for allowing air and gases to escape from the mold as the molten metal is injected. Inadequate venting can result in casting defects, such as air pockets, surface blemishes, or incomplete fills.

- Vents: Small channels or holes in the mold allow air and gases to escape during the injection process. Proper venting is crucial for ensuring that the molten metal flows smoothly into the cavity without becoming trapped by air. For example, in high-precision die casting for medical devices, precise vent placement ensures that gases do not create porosity or weak spots in the final part.

- Venting Design: The design of the vent system must balance efficiency and cost-effectiveness. Excessive venting can lead to the loss of molten metal or affect the integrity of the casting. In some cases, advanced simulation software is used to optimize the vent placement to achieve the best results. In industries like electronics, where parts require high precision and low tolerance for defects, advanced venting systems are essential for maintaining product quality.

Die casting molds consist of a range of components, each designed to perform a specific function to ensure the production of high-quality castings. From the cavity and core that define the shape of the part to the cooling channels that control solidification, every aspect of the mold plays a critical role in the overall success of the die casting process. By understanding and optimizing these components, manufacturers can achieve improved efficiency, reduce defects, and create high-precision parts for a variety of industries, including automotive, aerospace, electronics, and medical devices. With advancements in mold design and technology, the future of die casting looks poised to deliver even greater precision and productivity.

No comment