Unlocking the Power of Cold Chamber Die Casting: A Comprehensive Guide

Cold chamber die casting is a highly sophisticated metal-forming process that enables the production of high-precision, durable, and intricate metal components. Widely used in industries such as automotive, aerospace, industrial manufacturing, and consumer goods, this method is particularly well-suited for metals with high melting points, including aluminum, brass, and copper.

In this comprehensive guide, we will examine the cold chamber die casting process, its advantages, applications, and how it compares to other methods like hot chamber die casting. Whether you are a manufacturer looking to optimize production or a purchaser exploring the most efficient and cost-effective methods, this guide will provide valuable insights into why cold chamber die casting is the preferred choice for many precision applications.

What is cold chamber die casting?

Cold chamber die casting is a manufacturing technique that involves injecting molten metal into a steel mold under high pressure. Unlike hot chamber die casting, in which the furnace is integrated directly into the machine, cold chamber die casting requires the metal to be melted in an external furnace before being ladled into the machine’s injection chamber. This process is typically employed for metals with high melting points, such as aluminum, brass, and copper alloys, which are not suitable for hot chamber die casting due to the heat stress involved.

The cold chamber process enables manufacturers to create complex, precise parts that meet stringent quality standards. These parts are integral to applications in various industries, including automotive, aerospace, and industrial machinery.

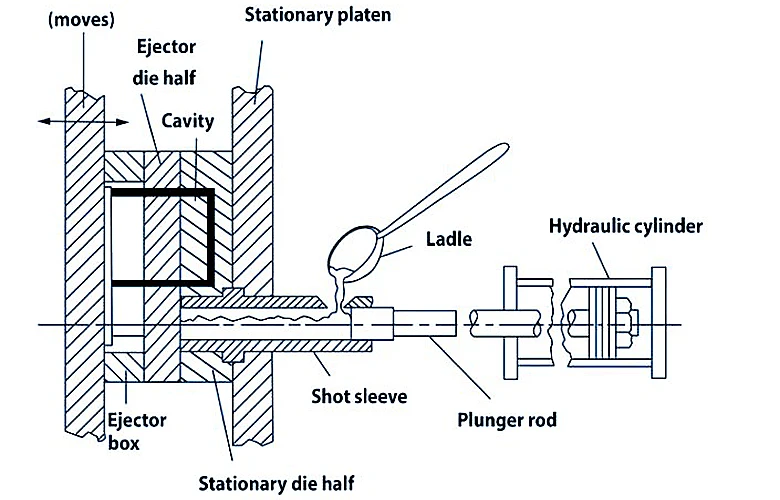

How Cold Chamber Die Casting Works?

The cold chamber die casting process consists of several key stages, each of which plays a crucial role in ensuring that the final product meets the desired specifications. Here’s an overview of how it works:

Metal Melting:

The process begins with the metal being heated in an external furnace to its required molten state. Once the metal reaches the optimal temperature, it is transferred to the cold chamber of the die casting machine.

Injection:

A plunger forces the molten metal into the die under high pressure, typically ranging from 1,000 to 30,000 psi, depending on the specific material and part design. The high-pressure injection ensures that the molten metal fills every cavity in the mold, allowing for the reproduction of fine details and complex geometries.

Cooling and Solidification:

After injection, the metal is allowed to cool and solidify in the mold. This process can take anywhere from a few seconds to several minutes, depending on the material and the complexity of the part. Once cooled, the mold is opened, and the part is ejected.

Post-Cooling Finishing:

In many cases, the cast part will require little to no additional finishing, thanks to the excellent surface finish achieved during the casting process. However, some parts may require additional machining or surface treatment to meet specific tolerances or appearance requirements.

Why Choose Cold Chamber Die Casting?

Cold chamber die casting offers a range of benefits that make it an ideal choice for manufacturing high-precision, durable components, particularly when working with metals that have high melting points. Here are some of the key advantages:

Key Benefits of Cold Chamber Die Casting

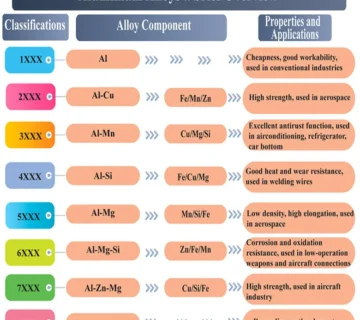

- Material Flexibility:

Cold chamber die casting is perfect for metals with high melting points, such as aluminum, brass, and copper. These materials are chosen for their strength, durability, and resistance to corrosion, making them ideal for critical applications in industries like automotive, aerospace, and industrial manufacturing. - High Precision and Accuracy:

The cold chamber die casting process delivers exceptional precision, making it ideal for parts with tight tolerances and intricate details. The high-pressure injection ensures that even complex geometries are faithfully reproduced, making it a preferred choice for high-performance parts. - Strength and Durability:

The high-pressure injection process produces dense, solid parts with excellent structural integrity. Cold chamber die-casting parts are known for their strength and durability, making them suitable for demanding applications where performance and longevity are critical. - Superior Surface Finish:

One of the key benefits of cold chamber die casting is the high-quality surface finish it produces. Parts often require minimal post-processing, making it an excellent choice for applications where appearance and smoothness are important. - Cost-Effectiveness for Large Production Runs:

Although the initial cost of tooling may be higher than other methods, cold chamber die casting offers significant cost savings for large-scale production runs. The efficiency of the process and the ability to use the same molds for many units help reduce the cost per part over time. - Low Waste Generation:

Cold chamber die casting produces minimal waste, as the molten metal is injected directly into the mold with little excess material. Any leftover metal can often be recycled, making the process more sustainable and cost-effective.

Applications of Cold Chamber Die Casting

Many industries that require precision and durability in their components extensively use cold chamber die casting. Below are some of the most common applications:

Automotive Industry

Cold chamber die casting is frequently employed in the production of automotive parts, such as engine blocks, transmission housings, cylinder heads, and wheels. Aluminum die castings, in particular, are valued for their strength-to-weight ratio, which helps reduce vehicle weight while maintaining performance.

Aerospace Industry

The aerospace sector requires parts that can withstand extreme conditions, including high temperatures and pressures. Cold chamber die casting is used to manufacture critical components such as aircraft engine parts, structural elements, and housings that must meet stringent safety and performance standards.

Industrial Equipment

Many industrial equipment manufacturers rely on cold chamber die casting to produce durable and precise parts like valves, pumps, electrical connectors, and gears. These components often need to be resistant to corrosion and wear, making the high-strength materials used in cold chamber die casting ideal for such applications.

Consumer Goods

Cold chamber die casting is also widely used for producing consumer goods like kitchen appliances, electronics enclosures, and decorative hardware. The process’s ability to produce smooth, high-quality finishes is particularly valuable for parts that will be visible to consumers.

Cold Chamber vs. Hot Chamber Die Casting: Key Differences

Both cold chamber and hot chamber die casting involve injecting molten metal into a mold under high pressure, but there are key differences between the two methods:

| Feature | Cold Chamber Die Casting | Hot Chamber Die Casting |

|---|---|---|

| Metal Type | Best for high-melting point metals (aluminium, brass, copper) | Best for low-melting point metals (zinc, magnesium, lead) |

| Furnace | External furnace | Integrated furnace |

| Injection Process | Metal ladled into the chamber | Continuous injection from the furnace |

| Cycle Time | Slower cycle times | Faster cycle times |

| Tooling Costs | Generally, higher tooling costs | Lower tooling costs |

| Maintenance | Less frequent maintenance | More frequent maintenance |

Conclusion

Cold chamber die casting is an indispensable manufacturing process for producing high-precision, durable, and complex parts, particularly for high-melting point metals like aluminium, brass, and copper. With its ability to handle intricate designs, high material strength, and excellent surface finishes, it is an ideal choice for industries such as automotive, aerospace, industrial manufacturing, and consumer goods.

Whether you are seeking to produce lightweight automotive components, robust industrial equipment, or intricate consumer goods, cold chamber die casting ensures precision and efficiency while delivering exceptional results at scale.

No comment