Common Casting Defect: Shrinkage Porosity in Die Castings

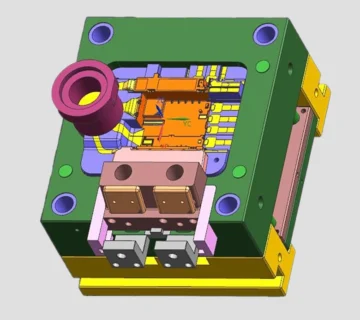

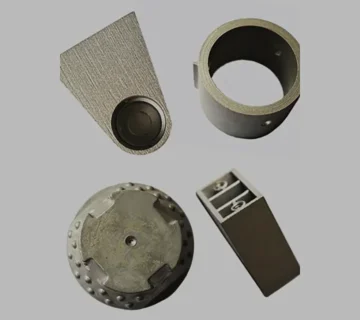

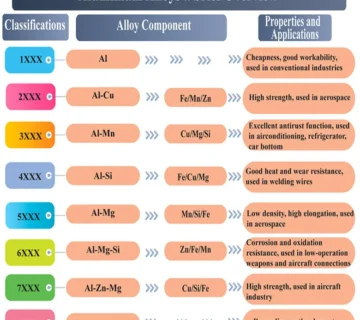

Shrinkage porosity, also known as shrink holes or cavities, occurs when molten alloy contracts during solidification without adequate feeding, creating voids inside the casting. This article explores its key characteristics, causes, and prevention techniques to enhance die casting performance and product reliability. ... Read More