DSW automobile casting components

At DSW, our automotive die-cast components are engineered for performance, durability, and efficiency across a wide range of applications.

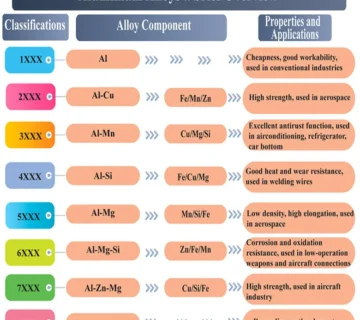

We specialise in the production of aluminium die-cast automotive parts, designed to provide exceptional strength and contribute to enhanced engine performance. Each material used in production is carefully selected and rigorously assessed to maximise functionality and broaden potential applications.

Aluminium alloys have become increasingly sought after in the market, thanks to their excellent properties and cost-effectiveness. Over the years, die casting technology has brought significant advancements to the manufacture of automotive engine components.

Manufacturing Process

Our aluminium die-cast automotive components are manufactured using advanced machinery and precision die-casting tooling, allowing for high-speed production and consistent quality. At DSW, we have earned a strong reputation in both commercial and private sectors through our commitment to excellence in aluminium automotive casting.

& Discuss

ENERGY

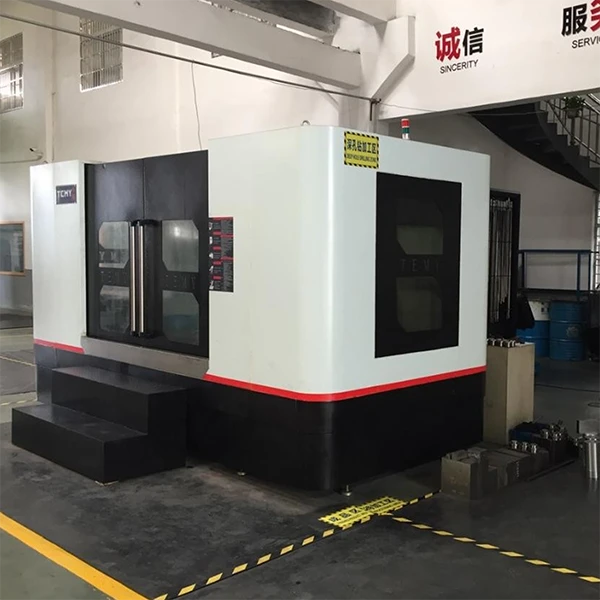

Advanced Equipment For Aluminum Die Casting Products

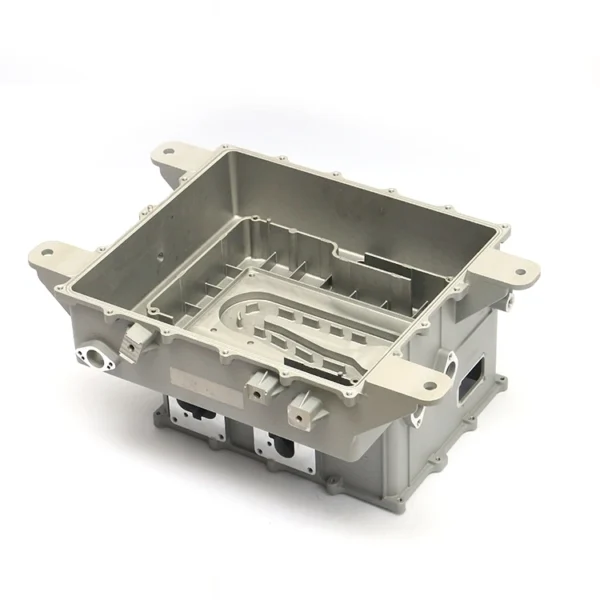

Automotive Aluminum Enclosure Projects

Hover Box Element

Hover Box Element

Engine Housing

- Material: ADC12

- Size: 660×480×350 mm

- Weight: 7300 g

- Machine Tonnage: 2500 T

- Surface Finish: Chromating

Hover Box Element

Hover Box Element

Automotive Battery Cover

- Material: ADC12

- Size: 470×284×99 mm

- Weight: 2580 g

- Machine Tonnage: 800 T

- Surface Finish: Chromating

Die Castings in the Automotive Sector

The automotive industry increasingly relies on die-cast parts to meet rising demands for fuel efficiency, performance, and reduced carbon emissions. With growing environmental concerns and stringent regulations, manufacturers are turning to lightweight materials like aluminum to create more fuel-efficient vehicles. Die-casting allows for the production of precise, durable components that are both lightweight and strong, making it an ideal solution for the automotive sector. At DSW, we specialize in producing high-quality automotive castings that meet precise specifications, ensuring optimal performance and reliability.

Key Die-Cast Products in the Automotive Industry

1. Engine Components

One of the most significant areas where die-casting is applied is in engine components. Cylinder heads made from die-cast aluminum alloys reduce engine weight, contributing to better fuel efficiency. Similarly, engine blocks—often die-cast using aluminum or magnesium alloys—are commonly used in smaller engines to reduce overall vehicle weight while maintaining performance.

2. Transmission Components

Die-casting also plays a critical role in producing various transmission components. Transmission housings, made from aluminum or magnesium, provide strength and durability while minimizing weight. Additionally, die-casting is used for shifter components, such as car shift levers, ensuring precision and reliability in the vehicle’s transmission system.

3. Automotive Structural Components

The structural integrity of a vehicle is crucial for both safety and performance. Die-cast components like chassis parts—including cross members and subframes—offer strength and rigidity while reducing overall weight. In addition, suspension components, such as control arms and steering knuckles, are commonly die-cast from aluminum or magnesium to improve vehicle handling and contribute to weight reduction.

4. Interior and Exterior Parts

Die-casting is widely used for producing both interior and exterior automotive parts. Components such as dashboard frames and panels require high precision and complex shapes, making die-casting the perfect solution. On the exterior, grille frames, trim parts, and decorative accents are often produced using die-casting to ensure durability and aesthetic appeal. Mirrors and mirror housings, made from die-cast materials like zinc, provide strength and weather resistance for exterior components.

5. Brake Components

Die-casting is also essential for the production of automotive brake components. Brake calipers, typically made from die-cast aluminum, offer the necessary strength and lightweight characteristics required in both high-performance and everyday passenger vehicles. Additionally, brake pedal assemblies are often die-cast to accommodate complex shapes and ensure durability.

6. Lighting and Cooling System Components

Lighting and cooling systems benefit from die-casting in multiple ways. Headlamp and tail light housings made from die-cast aluminum offer durability and the ability to withstand high temperatures. Similarly, components like radiator parts, including tanks and brackets, are die-cast for their cooling efficiency and strength. Thermostat housings also benefit from die-casting, ensuring they can endure the high temperatures present in engine systems.

7. Fuel System Components

Die-casting is used to produce key fuel system components, such as fuel pump housings that must withstand high pressures. The bodies of fuel injectors are often made using die-cast methods to ensure precision, strength, and durability under high-stress conditions.

8. Electronic and Sensor Housings

As vehicles become increasingly reliant on electronics, die-casting is used for producing sensor housings and electronic control units (ECUs). Sensor housings, often made from die-cast aluminum or zinc, house various sensors for monitoring temperature, pressure, and ABS. Similarly, the housings for automotive ECUs and other electronic components are frequently produced using die-casting, providing the precision and strength required for these critical systems.

Specialized Die-Cast Components

Automotive parts beyond the standard components mentioned above also utilize die-casting. These include stators, electric motor brackets, water pumps, engine sumps, stepper motors, gearbox covers, and heat sinks. These parts benefit from the die-casting process’s ability to produce intricate shapes with high dimensional accuracy, making them essential for advanced automotive applications.

What is the primary advantage of aluminium automotive castings?

- Weight Reduction: Aluminum is significantly lighter than steel, which reduces the overall weight of the vehicle. This results in improved fuel efficiency, better handling, and enhanced performance.

- Improved Fuel Efficiency: The lightweight nature of aluminum minimizes the energy required to move the vehicle, contributing to better fuel efficiency and lower carbon emissions, making it a crucial material for meeting environmental standards.

- High Strength and Durability: Aluminum castings provide excellent strength-to-weight ratios, ensuring that automotive parts are both durable and capable of withstanding high stress while maintaining a lighter weight for optimal performance.

AUTOMOTIVE CASTING:

FAQ GUIDE

No comment