Aluminium Alloy A383 (ADC12) – A Comprehensive Overview

Aluminium Alloy A383, also known as ADC12, is a popular material used for die-casting components across various industries. Due to its combination of affordability, excellent mechanical properties, and ease of casting, ADC12 is a highly sought-after material for both manufacturers and engineers worldwide.

Key Characteristics of ADC12

ADC12 is an aluminium alloy that stands out for its high silicon content and relatively low copper content, making it ideal for die-casting. Its attributes include:

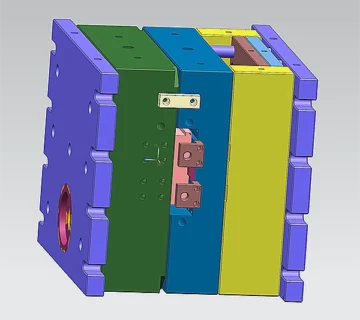

Enhanced die-filling properties: ADC12 ensures a smooth and accurate die-filling process, even for complex geometries.

Corrosion resistance: ADC12 offers strong resistance to both corrosion and oxidation, ensuring longevity and performance under challenging conditions.

Dimensional stability: The alloy maintains excellent dimensional accuracy during cooling, making it reliable for high-precision applications.

Affordability: It is a cost-effective choice for large-scale manufacturing without compromising on quality.

Advantages of Aluminium Alloy A383 (ADC12)

Lightweight and durable – ADC12 is ideal for applications requiring lightweight components without sacrificing strength.

Superior corrosion and oxidation resistance – Its resistance to corrosion and oxidation makes ADC12 highly reliable in outdoor and harsh environmental conditions.

Excellent machinability – The alloy’s ease of machining ensures high productivity during production.

Temperature resilience – Performs well under both high and low temperatures, making it versatile for a range of industries.

Cost-effective material – ADC12 is an affordable alloy, making it suitable for mass production of die-cast parts.

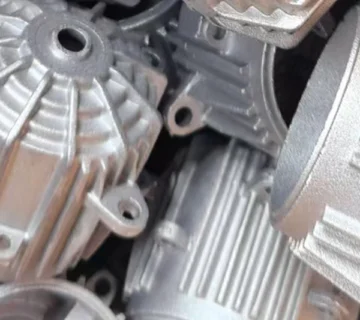

Applications of ADC12

Due to its outstanding mechanical properties, ADC12 is employed in various applications across multiple industries. Notable examples include:

Automotive Industry: ADC12 is widely used for producing engine blocks, cylinder heads, and other critical engine components due to its lightweight and high-strength properties.

Aerospace: The alloy is used in aerospace components where dimensional accuracy and weight reduction are crucial.

Electronics: ADC12 is commonly used for die-casting enclosures for electronic devices, power tools, and LED lighting.

Marine and Industrial Equipment: The alloy’s corrosion resistance makes it ideal for manufacturing marine equipment parts and other industrial components exposed to corrosive environments.

| Property | Value |

|---|---|

| Brinell Hardness | 75 HB |

| Rockwell B Hardness | 53 |

| Knoop Hardness | 109 |

| Vickers Hardness | 96 |

| Ultimate Tensile Strength | 310 MPa |

| Yield Strength | 150 MPa |

| Shear Strength | 199 MPa |

| Fatigue Strength | 140 MPa |

| Impact Strength | 4 J |

| Elongation | 3.5 % in 50 mm |

| Modulus of Elasticity | 71.0 GPa |

| Property | Value |

|---|---|

| Electrical Conductivity | 23.0 % IACS |

| Thermal Conductivity | 96 W/mK |

| Melting Point | 549 °C |

| Coefficient of Thermal Expansion | 21.1 µm/m°K |

| Specific Heat Capacity | 963 J/Kg.K |

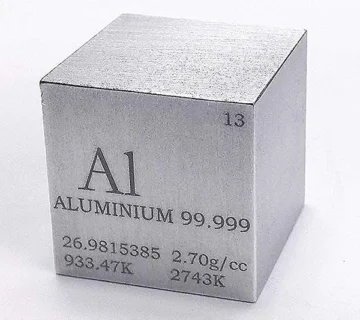

| Density | 2.74 g/cm³ |

| Element | Percentage |

|---|---|

| Aluminium (Al) | 79.65-82.65 % |

| Silicon (Si) | 9.5-11.5 % |

| Zinc (Zn) | 3.0 % |

| Magnesium (Mg) | 0.1 % |

| Tin (Sn) | 0.15 % |

| Copper (Cu) | 2.0-3.0 % |

| Manganese (Mn) | 0.5 % |

| Nickel (Ni) | 0.3 % |

| Iron (Fe) | 1.3 % |

| Other-Metallic | 0.5 % |

Comparison of ADC12 with Other Aluminium Alloys

ADC12 vs A380: A383, the modified version of A380, provides improved die-filling characteristics, which is particularly beneficial for more complex die-casting applications.

ADC12 vs A413: Compared to A413, ADC12 offers superior corrosion resistance and is less expensive. While A413 is also used in die-casting, it has lower corrosion resistance and is typically costlier.

ADC12 vs A360: A383 is easier to cast than A360, which is a more complex alloy to work with, making ADC12 a more efficient choice for mass production.

Conclusion

Aluminium Alloy A383 (ADC12) offers a balanced combination of mechanical strength, corrosion resistance, and affordability, making it an ideal choice for a wide range of die-casting applications. Whether in the automotive, aerospace, or electronics industries, ADC12’s versatility ensures it remains a go-to material for manufacturers seeking reliable, high-performance components.

No comment