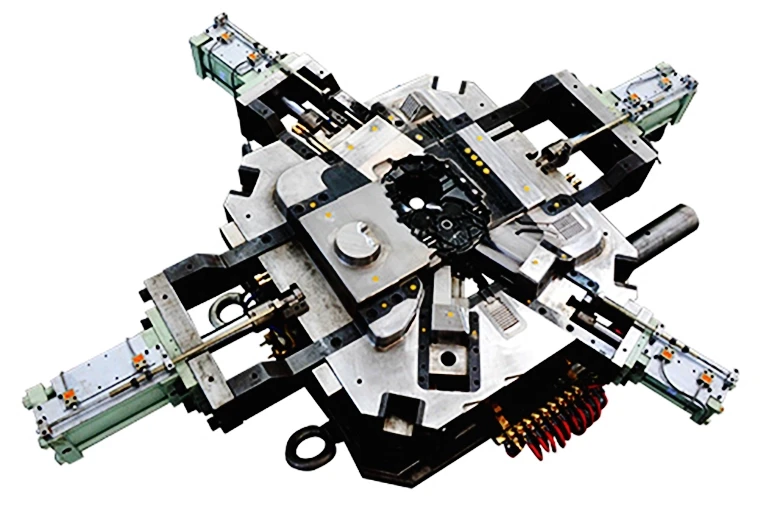

Casing Engine in aluminium die casting

DSW specialises in producing and manufacturing aluminium engine casings, motor covers, crankshaft casings, and truck engine housings designed to deliver optimal strength and enhance engine performance.

The materials used in production are meticulously selected to ensure durability and broaden the potential applications of the components.

Aluminium Engine Casing Specification

| Attribute | Details |

|---|---|

| Part Name | Engine Housing |

| Material | ADC12 |

| Size | 580 x 490 x 220 mm |

| Weight | 5800 g |

| Machine Tonnage | 2500 T |

| Surface Finish | Chromating |

| Production Process | Die Casting—Trimming—Deburring |

| Post Milling | CNC Machining |

| Testing | Leakage Inspection |

| Application | Automotive |

After manufacturing, the die-casting engine casing must undergo a 5-10 MPa pressure resistance test. Damage or leakage during the test is not permitted.

Application

Aluminium crankshafts and engine casings are commonly used in the automotive, aerospace, and industrial sectors due to their strength, durability, and lightweight properties.

In the automotive industry, they help reduce engine weight, which improves fuel efficiency and performance. These casings protect internal components like the crankshaft and bearings while providing excellent heat dissipation to prevent overheating.

In agriculture and construction, engines in tractors, excavators, and loaders require robust casings capable of withstanding dirt, shock loads, and continuous use.

In industrial machinery, aluminium casings deliver reliable performance in demanding environments, making them a preferred choice for various applications

1 review for Aluminium Engine Casing

There are no reviews yet.