Many industries rely on die casting as a fast and precise way to produce strong metal parts. A key application of die casting is the creation of protective covers. These die-cast covers, cases, and shells safeguard electronic, mechanical, and electrical components. They are strong, lightweight, and provide excellent heat management and physical protection. This makes die-cast enclosures an ideal choice for ensuring that critical components last longer and operate reliably.

DSW provides high-quality die-cast housings and enclosures for a wide range of industrial applications. Designed for durability, heat management, and precise fit, our die-cast solutions protect sensitive components in electronics, automotive, aerospace, telecommunications, and more.

What is die casting?

Die casting is a high-precision manufacturing process where molten metal is injected into a mould under high pressure. This process produces strong, consistent, and complex shapes suitable for industrial applications.

Common materials include:

- Aluminium: Lightweight, strong, excellent thermal conductivity

- Zinc: Cost-effective, corrosion-resistant, precise finishing

- Magnesium: Extremely light, suitable for mobile and aerospace components

Benefits of Die-Cast Enclosures

DSW’s die-cast housings offer multiple advantages for industrial equipment:

- Durability: Protects components from impact, vibration, and physical damage.

- Heat Dissipation: Metals like aluminium manage heat effectively for electronics and control units.

- Design Flexibility: Complex shapes and custom designs are easily achievable.

- Lightweight: Ideal for portable or mobile applications without compromising strength.

- Corrosion Resistance: Suitable for indoor and outdoor environments, ensuring long-term performance.

Industry Applications of Die-Cast Housings

Various industries utilize die-cast enclosures that offer essential protection and functionality. Below are some key sectors where die-cast casings, covers, and boxes are vital:

Electronics Industry

- Communication Equipment: Die-cast enclosures are used to house communication devices like radios, transmitters, and routers. They protect the internal circuitry from dust, moisture, and physical damage.

- Consumer Electronics: Devices such as set-top boxes, gaming consoles, and home automation equipment often feature die-cast housings for enhanced protection and heat management.

- Power supply units: To ensure safe operation and prevent overheating, power supply and battery management systems use die-cast containers.

Automotive Industry

Lighting Systems

Vehicle headlights, brake lights, and other lighting components often use die-cast housings for their strength, durability, and heat dissipation capabilities.

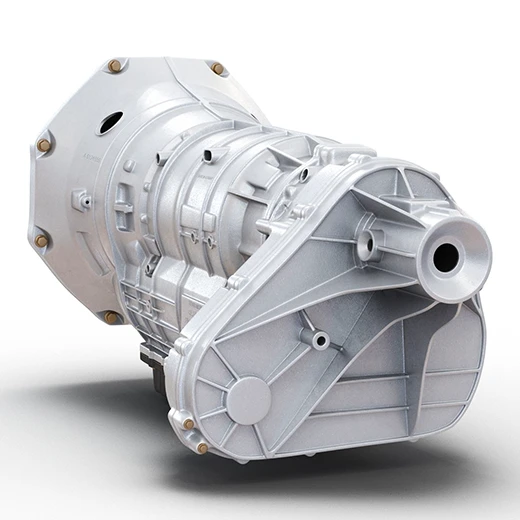

Control Modules

Die-cast enclosures, including gearbox shells and aluminum gearboxes, protect electronic control units (ECUs) and other critical modules from environmental damage, vibration, and heat.

Sensors and Actuators

Automotive sensors and actuators, particularly those in engine control systems, are housed in die-cast boxes or transmission bell cases to safeguard them against temperature fluctuations, physical impacts, and mechanical stress.

Clutch Bell Housing

Die-cast clutch bell housings provide robust protection for clutch components, ensuring reliable operation under high torque and thermal conditions.

Aviation industries

- Navigation and Communication Equipment: Die-cast enclosures are critical for protecting sensitive navigation and communication equipment used in aircraft and spacecraft.

- Instruments and Control Panels: Die-cast enclosures protect aircraft instruments from harsh environmental conditions and vibrations.

- Structural Components: Die-cast aluminum parts are commonly used in aerospace components due to their light weight and high strength-to-weight ratio.

Telecommunications Industry

- Cellular Base Stations: Die-cast enclosures are used for base stations and network hardware, protecting from harsh weather and ensuring reliable communication.

- Signal Distribution Boxes: Die-cast enclosures house equipment that controls and distributes signals, ensuring protection from interference and external elements.

Industrial Automation

- • Control Panels: Industrial control panels house switches, relays, and other components in die-cast casings, shielding them from mechanical damage, dust, and moisture.

- • Machine Parts and Components: Industrial machinery uses enclosures to shield components from contamination and guarantee smooth operation under various conditions.

Medical Industry

- Diagnostic Equipment: Medical devices such as ultrasound machines, X-ray equipment, and MRI scanners often rely on die-cast enclosures to protect their delicate electronic components.

- Portable Medical Devices: Portable health monitoring devices like blood glucose meters and heart rate monitors use die-cast protective enclosures to ensure durability and protection in mobile environments.

Energy and utility industries

- Electric Meters: Die-cast containers protect electric meters and utility monitoring devices from environmental elements and electrical interference.

- Renewable Energy Equipment: Die-cast enclosures are essential for solar power inverters, wind turbine control boxes, and other renewable energy devices, protecting them from exposure to the elements.

Defense and Military Applications

- Radars and Surveillance Equipment: Die-cast enclosures protect sensitive radar and surveillance equipment, ensuring it can withstand extreme temperatures, moisture, and physical damage.

- Weaponry and Communication Systems: Die-cast casings house military-grade communication systems and weaponry electronics to ensure their reliable performance in harsh environments.

HVAC Systems

- • Air conditioning and heating units: To ensure efficient operation, die-cast enclosures shield internal components in HVAC systems from dust, moisture, and temperature fluctuations.

- Thermostats and Controllers: These devices require sturdy and durable die-cast enclosures to protect their electronic circuits and sensors.

In Short

Die-cast enclosures, including housings, casings, boxes, and frames, provide a versatile, reliable, and cost-effective solution for various industries. Offering excellent protection, heat dissipation, and structural integrity, these enclosures are vital for safeguarding sensitive components in electronics, automotive, aerospace, telecommunications, and many other sectors. Their ability to ensure equipment performance and longevity is essential in the manufacturing and industrial landscape.

By choosing die-cast enclosures, businesses protect their components and enhance the overall performance and durability of their products, resulting in improved efficiency and customer satisfaction.