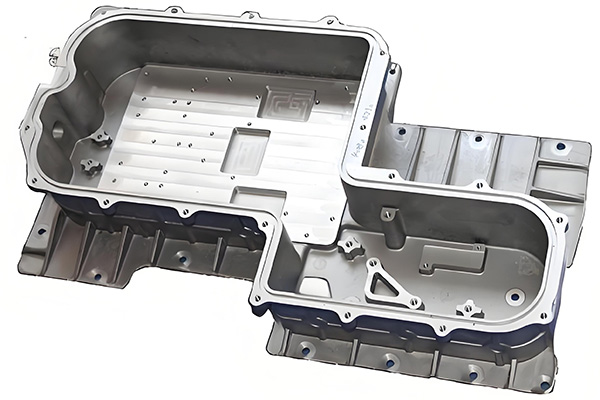

Aluminium Die Casting

High Precision, Flexibility, Die Casting Capacity Ranging from 80 to 2000 Tons.

Aluminum die casting is a versatile and reliable process used to produce lightweight, durable parts with excellent corrosion resistance. Ideal for high-temperature applications, it offers precision, efficiency, and superior surface finishes.

DSW is the one of leading aluminum die casting suppliers, specializing in high-quality, custom aluminum alloy parts for a range of industries including automotive, lighting ,home appliances, agricultural, machinery, aerospace, and medical.

Custom Aluminium Parts

Advantages of Aluminum Die Casting ?

Offers flexibility, stability, cost-efficiency, and versatile finishes for industries.

Aluminum die casting offers numerous benefits:

- Lightweight & High Strength: Excellent strength-to-weight ratio.

- Superior Surface Finishes: Including anodizing and smooth, polished surfaces.

- Complex Part Production: Capability for intricate geometries and large components.

- Design Flexibility: The die-casting process allows for complex and detailed designs with intricate features.

- High Production Rates: Efficient, low-labor process, ideal for mass production.

- Corrosion Resistance: Durable parts that withstand harsh conditions.

- Thermal & Electrical Conductivity: Perfect for automotive, aerospace, and electronics industries.

- Recyclability: Environmentally friendly and cost-effective.

These benefits make aluminum die casting suitable for industries like automotive, aerospace, medical, and more.

Processing of Aluminum Die Casting ?

Provides hot chamber, cold chamber die casing for industries.

Die casting is a precise manufacturing process that relies on different die types to produce high-quality parts.

Hot Chamber Dies

Used for metals with low melting points like zinc and magnesium, offering fast production.

Applications: Zinc die casting, small parts.

Cold Chamber Dies

Ideal for metals with higher melting points like aluminum, offering slower but more precise results.

Applications: Aluminum components, engine parts.

We employ both hot and cold chamber die casting techniques to meet diverse production requirements:

- Hot Chamber: Molten aluminum is injected into the hot chamber die through a gooseneck submerged in the molten metal, allowing for efficient production with high output rates.

- Cold Chamber: Molten aluminum is manually poured into a cold chamber, where a plunger then forces the metal into the die cavity under high pressure.

Both methods ensure the production of high-quality parts with minimal cycle times.

At DSW, we’re here to help you with every step—from the first design and prototyping to creating the die cast mold and full-scale production.

We’ll team up with you to tweak and improve your design, ensuring it’s perfect for die casting.

Die Casting Aluminum Alloys

Aluminum alloys are ideal for a variety of applications, thanks to their outstanding properties. Alloy 380 (or ADC12) is the most commonly used die casting alloy, valued for its versatility in meeting a wide array of customer needs. In addition, we work with several other premium aluminum alloys, including:

Industry Standard

- A380

- A383 (ADC12)

- ADC12

- B390

- A413

- A413HP

- K-Alloy

- A360

- ADC10

- ADC6

European Standards (EN)

- EN AC-46000

- EN AC-44300

- EN AC-47100

- ENAC44300

- ENAC 47100

pecial Alloys

- 43500

- AlSi12Cu

- AlSi9Cu3 (Fe)

- AlSi12Cu1 (Fe)

- AlSi12 (Fe)

- AlSi10MnMg

- AC4CH

- AlSigC3

- LM-24

- LM-27

- EZAC

Diverse applications

Aluminium Die casting is a versatile manufacturing process used in various industries to create complex, high-precision metal parts. The applications of die casting are widespread and include:

- Automotive Industry

Die casting is widely used in automotive manufacturing to produce critical components like engine blocks, transmission housings, cylinder heads, intake manifolds, brake components, fuel system parts, and structural components for lightweight vehicles. - Aerospace Industry

Die casting is employed in aerospace to create lightweight, durable, and high-strength components, including aircraft engine parts, landing gear components, structural frames, and fuel system parts. - Electronics Industry

In electronics, die casting is used to produce enclosures for devices such as mobile phones and laptops, heat sinks, connectors, terminals, and housings for electrical switches and circuit boards. - Consumer Goods

Die casting helps manufacture everyday consumer products, including kitchen appliances, power tools, toy parts, and lighting fixtures. - Industrial Equipment

Die casting is integral in producing industrial components like hydraulic parts, gearboxes, pumps, valves, and machinery parts. - Medical Devices

Die casting is utilized in the medical field to produce precision components, including surgical instruments, medical device housings, and diagnostic equipment parts. - Military and Defense

In the military and defense sector, die casting is used for weapon components, military vehicle parts, communication equipment housings, and aerospace defense parts. - Architectural and Building Components

Die casting plays a key role in creating architectural components such as window frames, door handles and locks, curtain rod brackets, and decorative hardware. - Renewable Energy

Die casting contributes to renewable energy applications by producing parts for wind turbines, solar panel frames, and energy-efficient lighting solutions. - Sports Equipment

Die casting is involved in manufacturing sports equipment, including bicycle parts, sporting goods accessories, and golf club heads.