Who we are …

About DSW Industrial

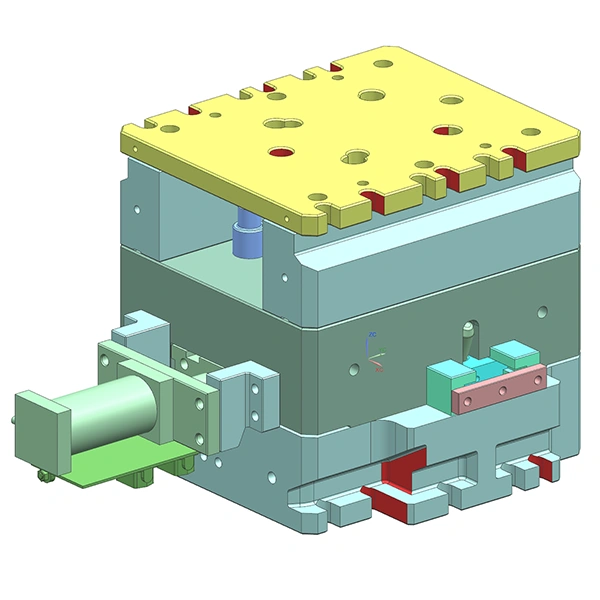

DSW Industry offers comprehensive solutions for customers around the globe, including die design, mold making, and finished casting parts. We provide a diverse range of die-cast components for machinery and various industrial sectors.

- AutomotivePump & motor housings

- LightingsLighting Fixtures

- MachineryEquipment relocation

- Electrical ServiceElectrical enclosures

Who we works …

Our Mission, What Can We Do?

At DSW Industry, our mission is to provide comprehensive, high-quality die-casting solutions to customers worldwide. From precision die design and mold manufacturing to the production of finished casting parts, we are dedicated to supporting global industries with reliable, customized components that enhance performance.

Expert Engineers

Industrial Ideas

Projects Support

Modern Equipment

In die casting, the design of the part significantly influences the feasibility and cost of manufacturing. If a part is poorly designed for the casting process, featuring complex geometries, thin walls, or unnecessary undercuts, it can lead to production challenges such as defects, difficulties in removing the part from the mold, or prolonged cycle times. Effective design ensures that the part is easy to cast and minimizes production issues.

It is an essential engineering practice that emphasizes creating products in a manner that facilitates, more cost-effective, and reliable manufacturing. The aim of DFM is to streamline the manufacturing process, lower production costs, minimize waste, and eliminate design features that are challenging or costly to produce.

In die casting, tolerance refers to the permissible limit or range of variation in the dimensions of a part. Precise tolerance is crucial in die casting because it indicates how closely a manufactured part matches the intended design. For die casting, tolerances usually range from ±0.1 mm to ±0.003 mm, depending on factors such as the material, part complexity, and the precision of the die and machinery.

People often select aluminum alloys like ADC12 and A380 for their excellent strength-to-weight ratio, corrosion resistance, and heat dissipation properties. In contrast, zinc alloys are well-suited for producing smaller, more intricate housings that offer superior dimensional stability.

When designing a die-casting die for enclosures, several key factors must be taken into account:

- Wall Thickness Uniformity: To prevent defects like warping and porosity.

- Draft Angles: Ensuring easy ejection from the die.

- Ribs and Bosses: Providing structural reinforcement and assembly functionality.

- Surface Finishing: Facilitating powder coating, painting, or anodizing post-production.

The die must be constructed from high-grade tool steel and maintained carefully to support large production volumes without degradation.

Proper alignment of the die halves is crucial for maintaining tolerances. Misalignment during the injection of molten metal can lead to shifts in part geometry, which can be especially problematic for components requiring precise fits or high precision.

We’re Hiring, Join Our Industry

Feel free to contact us and send your resume

We are experts in die casting

27 Years of Experience

Working with DSW Industry has been an exceptional experience. Their die casting housings consistently meet our high standards for quality and precision. Really appreciate their extra effort!

Nicolas CageIndustrial Inc.

If there were an award for Vendor of the Year, DSW Industry would be our top choice. As a highly demanding customer with large-scale requirements, we appreciate their consistent dedication and the way they consistently exceed expectations.

Jack CarterTechnology Systems

DSW Industry consistently provides aluminum casting enclosures of exceptional quality. Their attention to detail and reliability make them a trusted partner for our projects.