Die Casting Process and Mould Design

This comprehensive document explores the fundamental aspects of the die-casting process and die design, focusing on the analysis of die-cast mold structures. As a critical component of the pressure casting process, die casting molds represent a key element in ensuring quality production, accounting for approximately 70% of the overall impact on final product quality. This document provides detailed insights into the various structural components, classifications, and design considerations essential for effective die-casting operations.

Fundamentals of Die Casting Technology

Die-casting technology is one of the most efficient methods for producing complex metal components with high precision. The process involves injecting molten metal into a mold cavity under high pressure, resulting in parts with excellent dimensional accuracy and surface finish.

The three critical elements of pressure die casting are the die casting mold, the die casting machine, and the die casting process. These elements work harmoniously to ensure casting quality, improve production efficiency, and reduce manufacturing costs. Among these, the die-casting mould is the most crucial element, accounting for approximately 70% of the factors influencing the final product’s quality.

A well-designed die-casting mould, equipped with a rational gating system, an appropriate structural design, and precise manufacturing tolerances, can offset limitations in the die-casting machine, allowing for greater flexibility in process parameter adjustments. This highlights the importance of understanding die-casting mould structures and their influence on the casting process.

Components of Die Casting Technology

- Casting Alloys & Properties: The right alloy ensures optimal strength, thermal conductivity, and fluidity for high-quality results.

- Die Casting Part Design: Effective designs focus on material selection, wall thickness, draft angles, and features that facilitate mold filling and ejection.

- Die Casting Machines: Equipment can vary in pressure, speed, and automation, influencing casting quality and compatibility with specific requirements.

- Process Parameters: Temperature, pressure, and injection speed must be optimized for consistent, defect-free castings.

- Die Structure & Design: Well-engineered dies with proper gating, cooling, and ejection systems enhance casting quality and production efficiency.

Benefits of Die Casting

- High Dimensional Accuracy: Achieves tight tolerances and precise part dimensions.

- Excellent Surface Finish: Produces smooth surfaces, reducing finishing needs.

- Complex Geometries: Enables intricate designs that are difficult to achieve with other methods.

- High Production Rates: Suitable for fast, large-scale production.

- Cost-Effective: Efficient for high-volume runs, minimizing waste and material costs.

Die Casting Mold Classification

Die-casting tooling is essential for creating high-quality, precision parts. The structure of die-casting tooling is determined by several factors, including the die-casting machine used, the design requirements of the die-cast part, and the production volume. Understanding the different classifications of die-cast tools is crucial for selecting the right tooling for specific die-casting applications. Die-casting dies are categorized primarily by their structural characteristics, addressing various casting challenges. These classifications include single-parting-line dies and multiple-parting- line dies, each designed for different complexity levels in the die casting process. Furthermore, we can classify die-casting tools based on the core-pulling mechanisms they employ, which are crucial for producing parts with undercuts or internal features. Examples include side-action core-pulling dies, thread-unscrewing dies, and two-stage ejection dies.

Single Parting Line Die Cast Tools

Single-parting line die-cast tools are the simplest die-casting tooling, featuring a single parting surface between the fixed and movable halves. These tools are ideal for casting parts with simple geometries that can be easily ejected without requiring complex core-pulling mechanisms.

Multiple Parting Line Die Casting Moulds

Multiple parting line die-cast moulds are used to produce more intricate die-cast parts. These dies feature multiple parting surfaces, creating complex geometries that would be challenging or impossible with a single parting line. Multiple parting line die casting dies require advanced die casting design and manufacturing techniques, making them suitable for a wide range of applications.

Side-Action Core-Pulling Die Casting Dies

Side-action core-pulling die-casting dies incorporate hydraulic or mechanical systems to withdraw cores from the side of the die before ejection. These die-cast tools are essential for producing parts with undercuts or internal features, which are otherwise difficult to remove without causing damage. This design helps optimise the ejection process, ensuring smooth and efficient production.

Thread-Unscrewing Die-Cast Moulds

Thread-unscrewing die-casting tools specialize in creating parts with internal or external threads. Rotating mechanisms in these dies unscrew the threaded cores before part ejection. This advanced die-casting tooling solution is crucial for parts that require precision threading, such as automotive and industrial components.

Key Considerations in Die Casting Tooling

When selecting die-cast tools for production, it is important to consider die-casting tolerances and tooling life. High-quality tooling ensures precise dimensions and reduces the risk of defects in die-cast parts. Innovative tool and die solutions, such as high-pressure die-casting dies, contribute to achieving tight tolerances while maintaining production efficiency. Additionally, understanding the design of die-casting dies and the materials used, such as die-casting steel, is essential for optimizing tooling longevity and performance. With the right die-cast tooling and die-cast dies, manufacturers can achieve high production rates, cost-effective operations, and excellent surface finishes, making die casting a preferred solution for creating complex parts in industries like automotive, aerospace, and consumer goods.

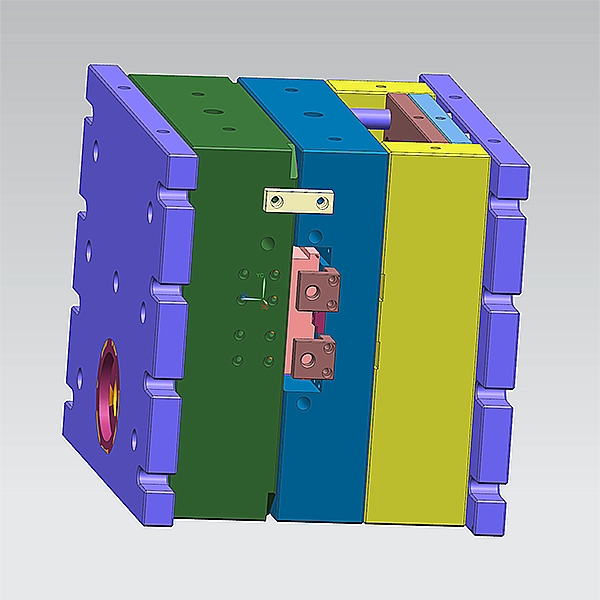

Basic Structure of Die Casting Molds

Die-casting molds consist of numerous components, each serving a specific function in the casting process. A thorough understanding of these components is essential for effective mold design and troubleshooting. Key components include fixed and movable mold halves, a gating system, a cooling system, an ejection system, and core-pulling mechanisms.

The fixed mould half (stationary die) remains attached to the die-casting machine’s stationary platen and typically contains the sprue through which molten metal enters the mould.

The movable mold half (ejector die) is attached to the moving platen and contains the ejection system, which pushes the solidified casting out of the mold after it opens.

Gating system: This system directs the flow of molten metal into the mold cavity, including components like sprues, runners, and gates.

Cooling system: it regulates the mould’s temperature, ensuring proper casting solidification.

The ejection system typically consists of ejector pins and plates, which remove the solidified casting from the mold.

Principles of Effective Die Casting Mould Design

The ultimate goal of die-cast mold design is to produce high-quality castings consistently, efficiently, and with minimal operator intervention. Key principles in die casting mould design include

Optimal performance: Consistent casting quality with minimal defects.

Robust design: Tolerance for process variations with minimal maintenance.

Economic efficiency: A balanced initial cost with long-term longevity and productivity.

Manufacturability: Practical and cost-effective to produce with available technology.

Effective die casting mould design requires careful consideration of all aspects of the mold, from material flow to thermal management and ejection mechanics. By focusing on simplicity, manufacturability, and attention to detail, designers can create molds that deliver consistent, high-quality castings, making the die-casting process more efficient and reliable.

No comment