Understanding the Density of Aluminum and Aluminum Alloys

Aluminum is one of the most widely used metals in industries ranging from aerospace to construction. Its low density, strength-to-weight ratio, and corrosion resistance make it a preferred choice for numerous applications. This article explores the concept of aluminum density, how it varies among different alloys, and why it is a crucial factor in determining aluminum’s performance in various applications.

What is Aluminum Density?

In simple terms, density refers to the amount of mass a material has in a given volume. For aluminum, the density gives us an idea of its weight and how it will behave in different environments and applications. The formula for density is:

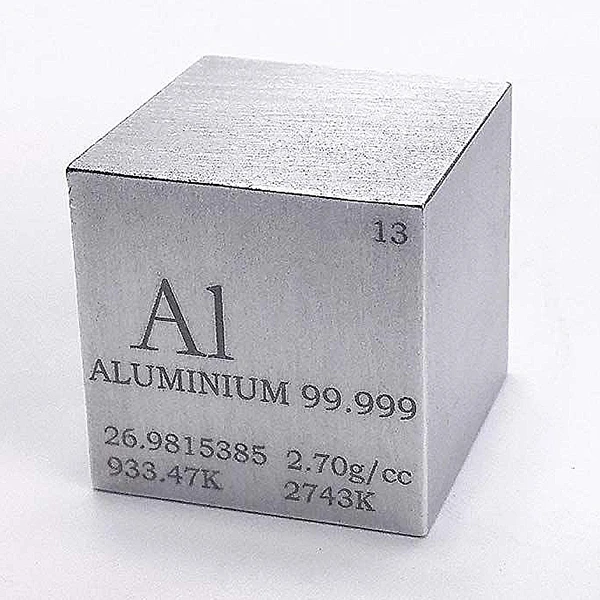

For pure aluminum, the density is approximately 2700 kg/m³ (or 2.70 g/cm³). This provides a baseline value, but it’s important to note that aluminum alloys can have densities that vary depending on the alloying elements used.

Density Variations Among Aluminum Alloys

While pure aluminum is used in some applications, it’s the alloys—combinations of aluminum with other metals—that dominate industrial uses. These alloys offer tailored properties, such as increased strength, better corrosion resistance, or enhanced thermal conductivity. The density of these alloys can range significantly due to the alloying elements.

For example, alloys in the 1xxx series, nearly 99% pure aluminum, have densities very similar to pure aluminum. In contrast, some alloys in the 7xxx and 8xxx series can have densities approaching 2.9 g/cm³, while certain 4xxx series alloys may be slightly lighter.

The alloying elements (such as copper, magnesium, zinc, and silicon) directly impact the density and mechanical properties of aluminum alloy. These elements can increase the material’s strength, hardness, and resistance to corrosion, but they also affect the alloy’s overall weight.

Factors Influencing Aluminum Alloy Density

Several factors can influence the density of aluminum alloys beyond their alloying elements, including:

Manufacturing Processes: The method used to create aluminum alloys—such as casting, rolling, or extrusion—can affect the material’s density.

Grain Structure: The arrangement of grains in the material affects its density, which in turn impacts its mechanical properties.

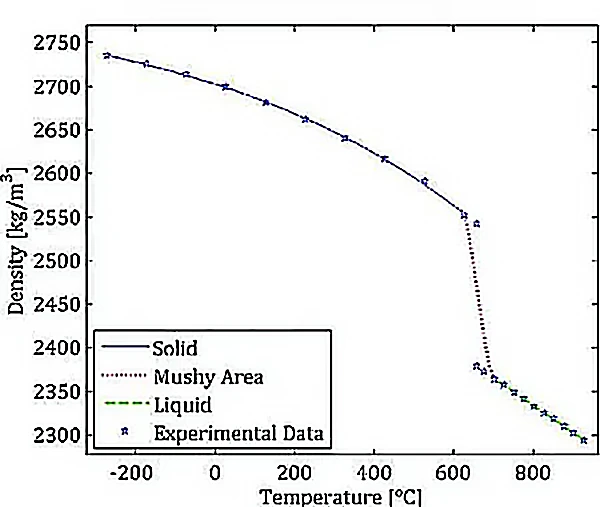

Temperature and Heat Treatment: The density of pure aluminium at room temperature (20 °C) is approximately 2.70 g/cm³. As the temperature increases, the density gradually decreases. For instance, at around 500 °C, it can fall to about 2.50 g/cm³, depending on the type of aluminium and the measurement method used. This change in density with temperature is crucial to consider during design and testing, especially in scenarios where materials are subjected to repeated heating and cooling or operate in high-temperature environments. Heat treatment processes, like annealing or solutionizing, can cause slight changes in the alloy’s density.

Impurities: Even trace amounts of impurities can change the material’s overall mass and volume, thus impacting its density.

Density of Aluminium Alloys

Aluminium alloys are blends of aluminium with other elements to improve strength, durability, and performance. Here’s a reference chart for the density of common aluminum alloys:

| Alloy | Density (kg/m³) | Density (lb/in³) | Density (g/cm³) |

| 1050/1060 | 2705 | 0.0977 | 2.71 |

| 1100 | 2710 | 0.0979 | 2.71 |

| 2011 | 2830 | 0.1022 | 2.83 |

| 2024 | 2780 | 0.1004 | 2.78 |

| 2219 | 2840 | 0.1026 | 2.84 |

| 3003 | 2730 | 0.0986 | 2.73 |

| 5052 | 2680 | 0.0968 | 2.68 |

| 6061 | 2700 | 0.0975 | 2.7 |

| 7075 | 2810 | 0.1015 | 2.81 |

| 7175 | 2800 | 0.1012 | 2.8 |

Why Does Aluminum Density Matter?

The low density of aluminum has several important implications for industries that rely on lightweight materials, including:

1. Lightweight and Fuel Efficiency

In industries such as aerospace and automotive, weight reduction is a key factor for enhancing fuel efficiency. Aluminum’s low density means that even large components can be much lighter than alternatives made from steel or other metals. For example, aircraft wings, automobile body panels, and engine components made from aluminum alloys contribute significantly to reducing overall weight and improving fuel economy.

2. High Strength-to-Weight Ratio

Aluminum alloys maintain an impressive strength-to-weight ratio, meaning they are strong enough to perform heavy-duty functions while remaining lightweight. This makes aluminum alloys ideal for structural applications, including building frames and bridges, where both strength and low weight are crucial.

3. Corrosion Resistance

The natural oxide layer that forms on aluminum gives it superior corrosion resistance compared to many other metals. This protective layer shields the material from rust and degradation, especially in harsh environments like marine or chemical industries.

4. Sustainability and Recyclability

Aluminum is highly recyclable and retains its properties after being recycled. The low density of aluminum also means that it consumes less energy to recycle compared to heavier metals. This contributes to sustainability, making aluminum a green choice for many industries.

5. Electrical Conductivity

Aluminum’s excellent electrical conductivity—almost twice that of copper—makes it a preferred material for power transmission lines and electrical wiring, where both weight and conductivity are critical.

6. Cost Efficiency

Aluminum’s lightweight nature means that it is less expensive to transport. This can result in significant cost savings for manufacturers who require large quantities of aluminum for production.

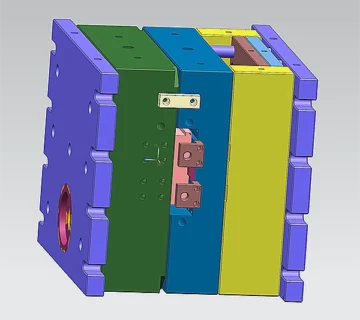

Aluminium Density in Different Casting Processes

Aluminium casting is a widely used process in the manufacturing of complex parts for industries such as automotive, aerospace, and consumer goods. While the theoretical density of pure aluminium is approximately 2.70 g/cm³, the actual density of cast aluminium parts can vary depending on the casting method used. This variation is primarily due to differences in porosity, solidification rates, and metal flow during the casting process.

| Casting Method | Typical Density (g/cm³) | Porosity Risk | Part Quality |

|---|---|---|---|

| Gravity Casting | ~2.65 – 2.68 | Moderate | Good |

| High Pressure Casting | ~2.60 – 2.66 | High | High precision |

| Low Pressure Casting | ~2.67 – 2.69 | Low | Excellent |

Applications of Aluminum Alloys

Given their low density and versatile properties, aluminum alloys are used in a wide range of industries:

Aerospace: Aircraft components, including fuselages, wings, and landing gear, rely on aluminum alloys for their lightweight yet durable properties.

Automotive: Aluminum alloys are used in vehicle body panels, engines, and wheels, contributing to weight reduction for better fuel efficiency.

Construction: Aluminum’s resistance to corrosion and its strength-to-weight ratio make it ideal for structural frames, windows, doors, and roofing.

Packaging: Aluminum is commonly used in packaging materials like cans, foil, and containers due to its low weight and recyclability.

No comment