How to Cast Aluminium: A Comprehensive Guide

Aluminium casting is a pivotal manufacturing process used to produce intricate components for various industries, including automotive, aerospace, and construction. Known for its lightweight and versatile properties, aluminium is ideal for producing durable, high-performance parts. This guide offers an in-depth examination of the key aluminium casting methods, their advantages, and their applications, providing essential information for manufacturers seeking to optimize casting operations.

Overview of Aluminium Casting

Aluminium casting involves the process of pouring molten aluminium into a mould to create parts with a defined shape. This technique is commonly used for manufacturing complex, precision parts in both small and large volumes. Aluminium casting is highly valued for its ability to produce components with excellent dimensional accuracy, high strength-to-weight ratio, and good corrosion resistance.

The casting process can vary depending on factors such as the complexity of the part, the required volume, and material properties. Key casting methods include sand casting, investment casting, and die casting, each offering distinct advantages suited to different production requirements.

Key Stages in the Aluminium Casting Process

1. Mould Design

The first step in the casting process is designing the mould, which can be made from materials like sand, steel, or ceramics, depending on the casting method. The mould is designed based on the part’s required shape, size, and surface finish. Advanced design tools, including Computer-Aided Design (CAD) software, are employed to ensure the mould is precise and meets the necessary tolerances.

2. Melting the Aluminium

Aluminium is melted in a furnace at temperatures around 660°C (1220°F). To ensure the best casting quality, the temperature of the molten aluminium must be closely controlled. Maintaining an optimal temperature ensures proper flow characteristics and reduces the likelihood of defects such as shrinkage or porosity.

3. Pouring the Molten Aluminium

Once molten, the aluminium is poured into the prepared mould. The pouring process must be carefully managed to avoid introducing air bubbles, which can lead to defects. The molten metal fills the mould cavity, taking the shape of the intended part.

4. Cooling and Solidification

After pouring, the molten aluminium is allowed to cool and solidify. The cooling rate must be controlled to minimize the risk of defects, such as shrinkage or cracking. The design of the gating system and the use of chilled moulds can help regulate the cooling rate and ensure a uniform solidification process.

5. Casting Removal and Post-Processing

Once solidified, the casting is removed from the mould. Post-processing may include trimming excess material, machining to achieve final dimensions, and surface treatments, such as anodizing or painting, to enhance the component’s properties and appearance.

Aluminium Casting Methods

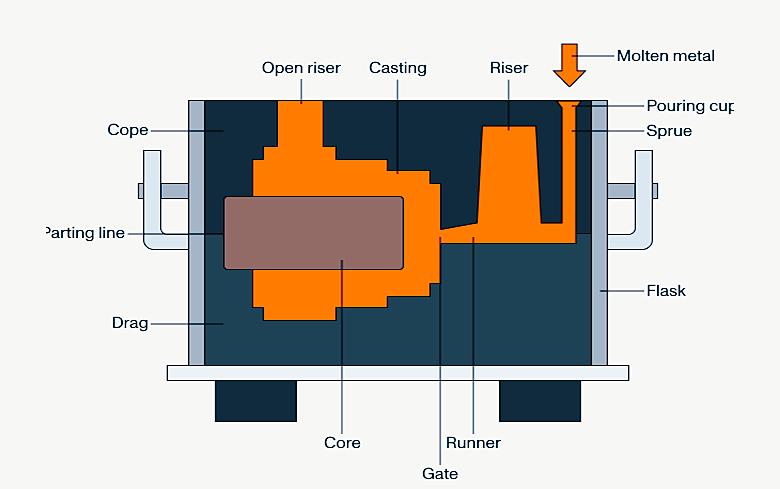

1. Sand Casting

Sand casting is one of the most established and widely used aluminium casting methods. In this process, a pattern is pressed into a mixture of sand and binders to form a mould cavity. Molten aluminium is poured into the mould and allowed to cool and solidify before the sand is removed to reveal the casting.

Advantages:

- Economical for both small and medium production runs.

- Capable of producing large and complex shapes.

- Highly flexible in terms of mould materials and part sizes.

Applications: Sand casting is often employed in manufacturing large, heavy parts, such as engine blocks and structural components in industries like automotive and construction.

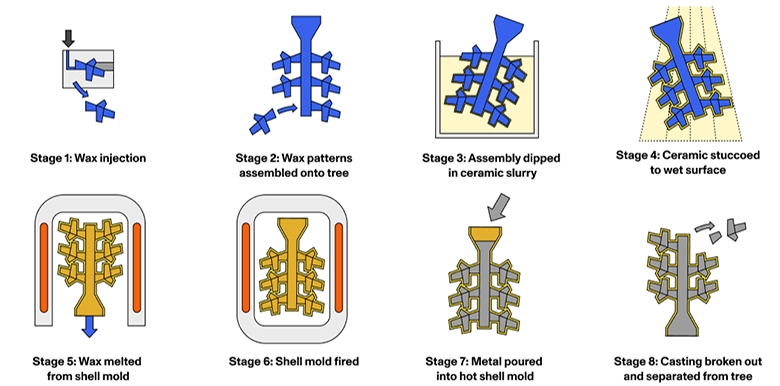

2. Investment Casting (Lost Wax Casting)

Investment casting, or lost wax casting, is a precision method that involves creating a detailed pattern, typically made from wax or thermoplastic, coated with a refractory material. Once the coating hardens, the pattern is melted away, leaving a cavity into which molten aluminium is poured. This technique produces parts with high dimensional accuracy and excellent surface finishes.

Advantages:

- Ideal for producing intricate geometries with tight tolerances.

- Provides a high-quality surface finish, reducing the need for further machining.

- Suitable for complex, thin-walled components.

Applications: Investment casting is widely used in industries requiring high-precision components, such as aerospace, medical devices, and fine machinery.

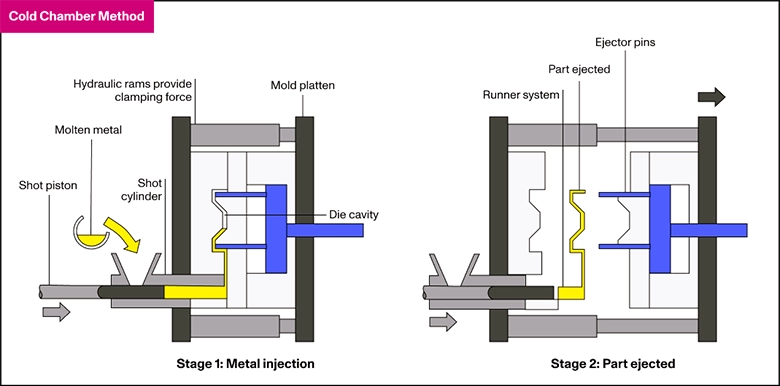

3. Die Casting

Die casting is a high-pressure method where molten aluminium is injected into a steel mould (die) under high pressure. The aluminium solidifies rapidly inside the die, and once cooled, the die is opened to eject the casting. Die casting is particularly suited to high-volume production runs.

Advantages:

- Highly efficient for mass production due to speed and consistency.

- Produces parts with excellent dimensional accuracy and uniformity.

- Suitable for parts with complex shapes, thin walls, and intricate details.

Applications: Die casting is predominantly used in the automotive, electronics, and consumer goods industries, producing high-precision components like engine parts, electrical housings, and consumer electronics.

| Alloy | Alloy Code | Casting Process | Description | Common Applications |

|---|---|---|---|---|

| A356 | 356.0 | Sand Casting, Investment Casting, Die Casting | A versatile alloy with good castability and strength, especially in heat-treated conditions. Good corrosion resistance. | Automotive, aerospace, and structural components. |

| A380 | 380.0 | Die Casting | High fluidity, good castability, and excellent dimensional stability. It is the most common alloy used in die casting. | Automotive parts, electronic housings, and industrial components. |

| A413 | 413.0 | Die Casting | Provides high strength and excellent resistance to corrosion. Suitable for thin-walled castings. | Automotive wheels, structural components, and other high-strength applications. |

| A201 | 201.0 | Investment Casting | High-strength alloy with excellent wear and fatigue resistance. It has lower ductility compared to other alloys. | Aerospace and high-performance engine components. |

| A356.2 | 356.2 | Sand Casting, Investment Casting | A modified version of A356 for better fluidity and easier casting. Maintains excellent mechanical properties and corrosion resistance. | Aerospace, automotive, and marine applications. |

| A535 | 535.0 | Sand Casting | Corrosion-resistant alloy, ideal for marine and marine-related applications. | Boat parts, offshore structures, and other marine environments. |

| A319 | 319.0 | Sand Casting, Die Casting | Good strength and castability. Often used for parts requiring a good balance of strength and corrosion resistance. | Automotive engine parts, pump housings, and similar components. |

| A413.0 | 413.0 | Die Casting | Alloy with high strength and superior resistance to corrosion and wear. | Automotive, aerospace, and other structural applications. |

| A356.0 | 356.0 | Sand Casting, Investment Casting | Excellent fluidity and casting performance with high strength, commonly heat-treated for enhanced mechanical properties. | Aerospace, automotive, and structural components. |

| A518 | 518.0 | Investment Casting | Offers excellent corrosion resistance and good strength, particularly in marine environments. | Marine applications, particularly for components exposed to saltwater. |

| A713 | 713.0 | Sand Casting | Good corrosion resistance, especially when exposed to harsh environments, and offers good strength. | Marine, military, and automotive applications. |

| B380 | B380.0 | Die Casting | Provides good fluidity and excellent dimensional stability, primarily used for thin-walled castings. | Automotive parts, machinery components, and electronics. |

Common Defects in Aluminium Casting

Aluminium casting, like any manufacturing process, is susceptible to certain defects. The most common casting defects include:

Porosity: Gas bubbles trapped in the casting that weaken the material.

Shrinkage: Gaps or voids caused by the aluminium contracting as it cools.

Misruns: Incomplete filling of the mould cavity, resulting in an unfinished part.

To minimise these defects, manufacturers can:

Optimize mould design and gating systems to ensure proper flow and prevent air entrapment.

Control the cooling rate to avoid excessive shrinkage.

Use high-quality materials and maintain precise temperature control throughout the process.

Benefits

Aluminium casting offers several key advantages over other manufacturing techniques:

Cost Efficiency: Ideal for both low and high-volume production, especially in methods like sand casting and die casting.

Design Flexibility: Capable of producing intricate geometries, which is often not feasible with traditional machining.

Material Properties: Aluminium castings provide a high strength-to-weight ratio, good corrosion resistance, and thermal conductivity, making them suitable for demanding applications.

Speed and Precision: High-volume casting methods, particularly die casting, allow for fast production while maintaining tight tolerances and consistent quality.

Final Thoughts

Aluminium casting remains a vital process for producing high-precision, high-performance components across multiple industries. Whether using sand casting, investment casting, or die casting, each method offers distinct advantages based on the application requirements. By selecting the appropriate casting technique and closely controlling each stage of the process, manufacturers can produce parts that meet stringent quality standards.

For manufacturers seeking reliable aluminium casting solutions, DSW offers expert services tailored to meet your specific needs. Contact us today to learn more about our aluminium casting capabilities and how we can support your manufacturing processes.

No comment