Die Casting Mold Manufacturer

24 years of experience, with a high tolerance of up to 0.02mm.

DSW is a privately owned business that has been serving the mold and die industry since 2004. Based in Ningbo, we’ve consistently delivered top-quality die cast dies and continually raised the bar for manufacturing standards.

We design our die-cast tooling to be compatible with casting machines that range from 50 to 2,000 tonnes, accommodating die castings weights of up to 20 kg. This versatility ensures we can meet the demands of diverse manufacturing environments, from simple to highly complex die designs.

We are Expert In

DSW is fully prepared to support every phase of your aluminum alloy casting project, from design and prototyping to die manufacturing and full-scale production.

What is a die casting die ?

Meet our team members and our work places

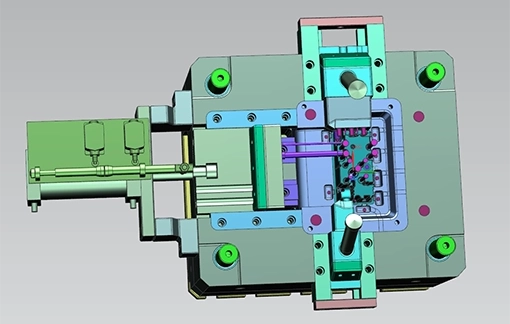

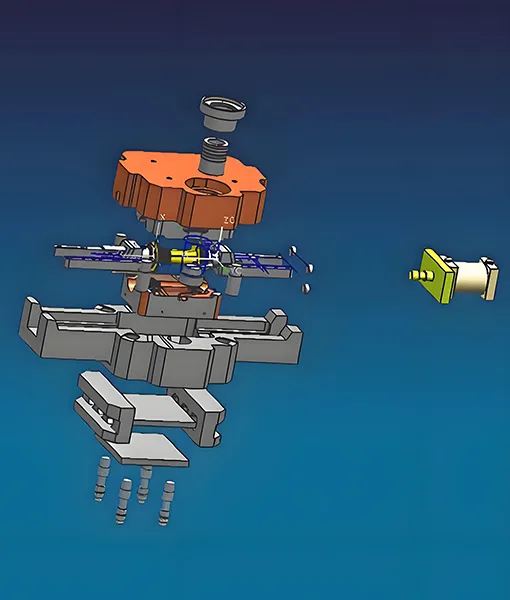

A die-casting die or die cast molds is a precision tool utilized in the die-casting process. This manufacturing method produces metal parts by injecting molten metal under high pressure into a mold cavity.

The die-casting die comprises two main components: the core and the cavity. The core is internal, while the cavity shapes the cast part. The precise engineering of these dies ensures tight dimensional tolerances, smooth surface finishes, and consistent quality in every casting.

Types of Die Cast Dies

Several types of die-casting tooling are available, each designed to meet specific requirements in terms of part complexity, material, and production volume.

Single Cavity Die

Description: Engineered to produce one part per cycle, perfect for smaller production runs or single-part needs.

Applications: Suitable for low-to-medium volume or high-precision components.

Single Cavity Die

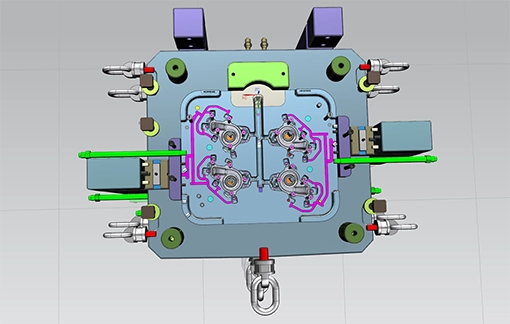

Multi Cavity Mold

Multi Cavity Mold

Description: Multi-cavity dies manufacture several identical parts per cycle, improving efficiency and lowering costs. The part size and tool design determine the number of cavities.

Applications: Suitable for medium- to high-volume production of simpler components.

Before Making a Casting Die?

Fully understand the function and assembly of the casting.

Before creating a die-cast die, it is essential to thoroughly understand the casting’s function, assembly, and how all the components work together. This understanding serves as the basis for designing a die that meets the necessary performance, quality, and manufacturability standards.

- Ensuring Proper Fit

- Optimizing Part Design

- Improving Tooling Design

- Ensuring Efficient Assembly

- Prevent Manufacturing Defects

- Optimizing Cooling and Heating

Steel for Die Cast Tooling

Commonly used steels for die-casting molds include H13, 2344, SKD61, 8407, 8418, and 1.8433, each providing distinct properties tailored to specific applications.

| Steel Grade | Properties | Applications | Advantages |

| H13 | Toughness, high thermal fatigue resistance, high strength | Aluminium-magnesium alloys | Excellent resistance to wear and thermal fatigue; ideal for high-volume, multi-cycle applications. |

| 2344 | High purity, high performance, excellent heat resistance | High-quality die casting | Suitable for high-precision, high-performance applications; longer lifespan than lower-grade steels. |

| SKD61 | High purity, good dimensional stability, wear resistance | Precision moulds, high-performance metals | Excellent heat resistance and durability; ideal for high-precision applications. |

| 8407 | High-end, excellent wear resistance, high thermal conductivity | Large, complex aluminium alloy die casting | Long-lasting with superior performance; ideal for complex and large moulds. |

| 8418 | High-end, excellent heat resistance and thermal conductivity | Large-scale aluminium die casting | Durable for high-temperature and high-stress applications. |

| 1.8433 | High temperature softening resistance, good thermal conductivity | Small die casting moulds | Extends die life and improves surface finish in small moulds. |

| 40Cr | Good wear resistance, high tensile strength, medium hardness | Zinc alloy die casting | Good strength and toughness; cost-effective for zinc die casting. |

| 30CrMnSi | High wear resistance, outstanding toughness | Zinc alloy die casting | Excellent for producing durable and high-quality zinc die castings. |

| 40CrMo | High strength, good wear resistance | Zinc alloy die casting | Good toughness and heat resistance, suitable for higher-stress zinc applications. |

Casting Aluminum Alloy

Here’s a table listing the aluminum alloys for high-pressure die casting and their properties.

| Alloy | Description | Common Applications |

| A360 | Good fluidity, corrosion resistance, and high strength. | Automotive parts, industrial machinery |

| A380 | Widely used, excellent castability, good strength and durability. | Automotive parts, electrical enclosures, appliances |

| A383 | Variant of A380 with improved casting characteristics. | Automotive, electrical, and consumer goods |

| A413 | Excellent fluidity, ideal for thin-walled castings. | Thin-walled, intricate parts, electronics |

| A356 | High strength, fatigue resistance, and weldability. | Aerospace, automotive, marine applications |

| A201 | High tensile strength, used in heavy-duty applications. | Engine blocks, structural components |

| A356.2 | High-performance properties for complex geometries and strength. | Aerospace, automotive, and high-performance parts |

| B390 | High wear resistance, often used for automotive parts like engine blocks. | Automotive, engine blocks, heavy-duty parts |

| A535 | Higher corrosion resistance and strength. | Marine, industrial, and automotive applications |

| A413.0 | Good fluidity, precision casting for complex parts. | Precision die casting, complex components |

The Industries We Serve

Our services are capable of producing complex, high-tolerance components at scale, serving a wide range of industries, including automotive, aerospace, machinery, medical, energy, electronics, lighting, and more.

Automotive

Electronics

Electrical

Lighting

Machinery

HVAC Industries

Clients & Partners

We work closely with our clients and partners to provide die cast dies and die castings worldwide.

Start New Project Today …

Partner with DSW Industry, where precision dies and die casting meet performance.