Low Pressure Die Casting

Minimal porosity, Complex geometries, Casting Capacity Ranging from 80 to 800 Tons.

Low-pressure casting is a metal casting process that involves injecting molten metal into a mold using low pressure, typically between 1 and 2 bar (15 to 30 psi).

Metals such as aluminum, brass, and copper alloys often use this method to create intricate, high-quality components with excellent surface finishes.

Since 2010, DSW has specialised in high-quality low-pressure casting for various industries, including the automotive, lighting, home appliances, agriculture, machinery, electrical, and medical sectors.

We Are Pressional In

Advantages of Low Pressure Die Casting ?

Offers flexibility, stability, cost-efficiency, and versatile finishes for industries.

Low-pressure die casting offers several advantages, particularly for producing high-quality, complex metal components. Some key benefits include

Wall Thickness

Wall thickness typically ranges from 2 mm to 6 mm, though it may vary depending on the part’s size and complexity.

Complex Shapes

Like gravity die casting, low-pressure die casting can produce intricate and complex geometries. This process is particularly beneficial for parts with detailed internal features and geometries that may be challenging to achieve with other methods.

Tolerance

Low-pressure die casting typically achieves tolerances of ±0.5 mm for dimensions up to 25 mm, with an additional ±0.02 mm for each extra 25 mm. While this tolerance is slightly broader than gravity die casting, it is still suitable for most industrial applications, mainly when producing larger components.

Material Flow and Solidification

Low-pressure die casting offers greater control over the flow of molten metal into the mould cavity, which is particularly advantageous for thin-walled or complex components. This control effectively reduces internal porosity and meticulously manages the solidification process to enhance the part’s mechanical properties.

Improved Surface Finish: Because the procedure is controlled, it frequently produces a smoother surface finish, eliminating the need for additional finishing operations.

Cost-effective for Certain Materials: It is beneficial for making parts in materials like aluminium, magnesium, and copper alloys, which require high material strength and minimal porosity.

These benefits make low-pressure die casting the favoured approach in automotive, aerospace, and energy industries, where quality and precision are essential.

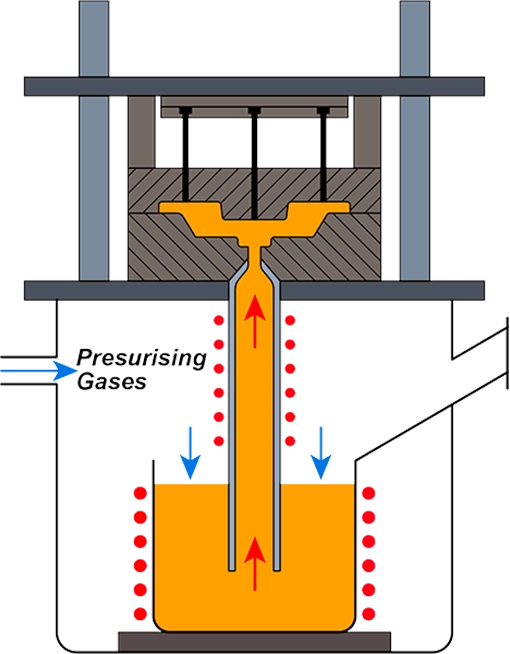

Processing of Low Pressure Casting ?

Allows for precise, high-quality castings, especially for complex or thin-walled components.

The LPDC casting process is as follows: Dry compressed air is introduced into a sealed crucible (or sealed chamber), and the molten metal is driven by gas pressure through the riser tube into the direct gating system. From there, it flows smoothly through the inner runners. It fills the mold cavity, with the gas pressure on the metal surface inside the crucible maintained until the casting is fully solidified. Once solidification is complete, the gas pressure is released, allowing the unsolidified metal in the riser tube to flow back into the crucible. The mould is then opened, and the casting is removed.

Low-pressure die casting is distinct from high-pressure die casting in terms of equipment, process, and product characteristics. The pressure applied in low-pressure die casting is relatively low, typically ranging from 20 to 60 kPa, with the pressure source being gas.

Due to the low pressure, the metal fills the die more slowly, which reduces production efficiency. However, this slower filling process improves product porosity and allows the casting to undergo heat treatment.

Overall, low-pressure die casting acts as a balance between high-pressure die casting and gravity die casting.

At DSW, we’re here to help you every step of the way—from the very first design and prototyping to creating the die cast mold and full-scale production.

We’ll team up with you to tweak and improve your design, making sure it’s perfect for die casting.

Casting Aluminium Alloys

In low-pressure (LPDC) casting, typical aluminium alloys that are commonly used include:

| Alloy | Common Name | Key Properties | Notes |

|---|---|---|---|

| A356 | AlSi7Mg0.3 | High strength, excellent corrosion resistance, heat treatable (T6) | Most widely used structural casting alloy |

| A357 | AlSi7Mg0.6 | Higher strength than A356, excellent corrosion resistance | More Mg, suitable for critical components |

| A319 | AlSi6Cu2Mg | Good castability, moderate strength, good corrosion resistance | Used in automotive engine components |

| A206 | AlCu4.5Mg | Very high strength, heat treatable (T6, T7) | Aerospace-grade, lower corrosion resistance |

| A360 | AlSi10Mg | Excellent corrosion resistance, good strength | Not heat treatable, used in complex thin-wall parts |

| A413 | AlSi12 | Excellent fluidity, good pressure tightness | Not heat treatable, for intricate castings |

| B390 | AlSi17Cu4Mg | Very high wear resistance, high hardness | Poor machinability, used in engine blocks |

| EN AC Alloy | Equivalent US Alloy | Key Properties | Notes |

|---|---|---|---|

| EN AC-42100 | A356 | High strength, excellent corrosion resistance, heat treatable | Equivalent to A356 |

| EN AC-42200 | A357 | Same as above but slightly higher strength | For stronger applications |

| EN AC-43200 | A319 | Moderate strength, good castability | Similar to A319 |

| EN AC-43400 | AlSi10Mg | Good fluidity, moderate strength, weldable | Similar to A360 |

| EN AC-44300 | ADC10 | Excellent castability, fair strength | Pressure die casting |

| EN AC-47100 | ADC12 | Very good castability, moderate strength | Mass production, not heat treatable |

| EN AC-43500 | AlSi12Cu | Excellent fluidity, used for thin walls | Similar to A413 |

| Trade Name / Code | Common Name / Std | Key Properties | Notes |

|---|---|---|---|

| ADC12 | A383 / EN AC-47100 | Excellent castability, moderate strength | Most popular in Asia for HPDC |

| ADC10 | – | Similar to ADC12 but with lower Cu | Used in Japan and Korea |

| LM24 | A380 equivalent | Good castability, moderate strength | Common in the UK |

| LM27 | – | High corrosion resistance, good strength | Used in marine & electrical |

| EZAC® | – | High strength, good castability | Proprietary alloy (Curamik/ALCOA) |

| K-Alloy | Modified A356 | Excellent corrosion resistance & pressure tightness | Ideal for marine & outdoor lighting |

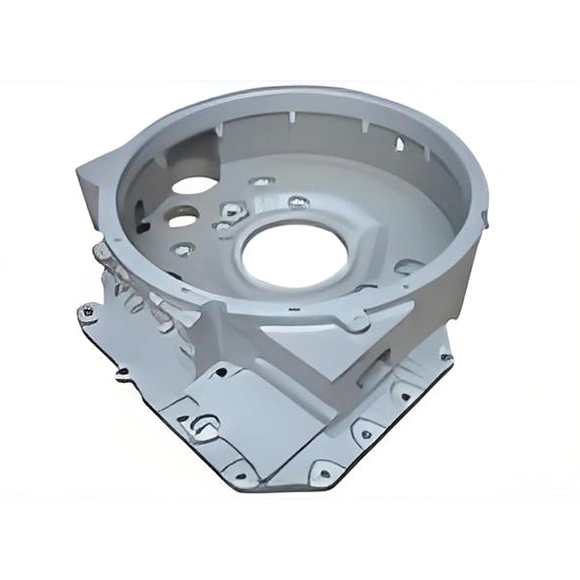

Diverse Applications of Low-Pressure Die Casting

Low-pressure die casting is a specialised process using gas pressure to create lightweight, high-precision parts. It is ideal for components requiring excellent mechanical properties, minimal porosity, and fine surface finishes. It is commonly used in the following industries:

Automotive Industry

Low-pressure die casting is used in automotive manufacturing for producing large, complex components such as engine blocks, transmission housings, cylinder heads, and intake manifolds. These parts benefit from the process by ensuring internal strength, minimal porosity, and precision in critical automotive applications.

Aerospace Industry

In aerospace, low-pressure die casting is used to produce structural components like fuselage parts, engine casings, and landing gear components. The process is ideal for producing high-strength, lightweight, and complex parts required in aerospace manufacturing.

Electronics Industry

Low-pressure die casting is used to make enclosures for electronic devices, such as heat sinks, and housings for electrical equipment. The process provides precise dimensional control and excellent surface finishes, which are critical for managing heat dissipation.

Industrial Equipment

Low-pressure die casting is used to manufacture durable components for industrial machinery, including hydraulic parts, valves, pumps, and gearboxes. The process ensures strong mechanical properties and minimal porosity, making it ideal for high-resistance parts.

Renewable Energy

In renewable energy applications, low-pressure die casting is used for parts in wind turbines, solar energy systems, and energy-efficient lighting. The process is ideal for producing components requiring strength, durability, and lightweight properties.

Medical Devices

Low-pressure die casting produces precision components for medical devices, such as diagnostic equipment housings and medical instrument parts. It ensures minimal porosity, which is essential for the safety and reliability of medical components.